Global beverage major Coca-Cola launched its first-generation plant-based beverage bottle PlantBottle™ for sustainable packaging in 2009. The bottle was made of 30% monoethylene glycol (MEG) derived from sugarcane residue and 70% terephthalic acid (bPTA) derived from oil-based sources.

The company entered agreements with three biotechnology companies, including Virent, an energy technology company based in the US, Gevo, a biofuel company based in the US, and Avantium, a technology company based in the Netherlands, in December 2011 to commercially develop completely bio-based material for the next-generation PlantBottle packaging. It was a significant research and development (R&D) investment by the company in packaging innovation.

Coca-Cola distributed more than 35 billion of its first-generation, 30% plant-based PlantBottle bottles in approximately 40 countries by June 2015, prior to the launch of its 100% plant-based (rPET) PlantBottle packaging.

Next-generation PlantBottle development details

The company introduced its first prototype for a fully-recyclable 100% rPET PlantBottle, excluding the cap and label, using lab-scale production methods, in June 2015, as part of its next-generation sustainable packaging initiative.

The 100% rPET PlantBottle was made by combining sugars converted from plant-based materials to form plant-based monoethylene glycol (bMEG) and bPTA converted from plant-based paraxylene (bPX).

The company co-owned and co-developed the technology to produce bMEG with Changchun Meihe Science & Technology.

Coca-Cola unveiled the 100% rPET prototype bottle, excluding cap and label, using only the commercially-scalable technologies in October 2021. In the same month, Coca-Cola and Changchun Meihe partnered with UPM, a paper mill company based in Finland, for the commercialisation of technologies involved in the efficient conversion of second-generation biomass to bMEG. UPM is constructing a state-of-the-art biorefinery in Leuna, Germany, for the production of biomaterials.

The 100% plant-based plastic bottles represent a significant technological advance, eliminating virgin oil-based PET from commercially produced bottles. The technology represents a breakthrough in sustainable and low-carbon packaging solutions, providing a welcome alternative to fossil-fuel based packaging.

Benefits

The PlantBottle made from sugarcane-based ingredients helps to reduce carbon dioxide emissions and leaves a smaller environmental footprint.

Coca-Cola aims to use leftover agricultural goods to make plant-based PET in order to reduce its carbon footprint. Most of the municipal recycling systems in the US accept plant-based bottles for recycling.

Coca-Cola’s collaborations regarding its PET bottles

Wisconsin-based company Virent produces bPX under the trademark BioFormPX™ for the 100% rPET resin of Coca-Cola’s new plant-bottles, under long-term Joint Development and Supply Agreements. Virent opened its full-scale commercial plant, producing bPX, in 2015.

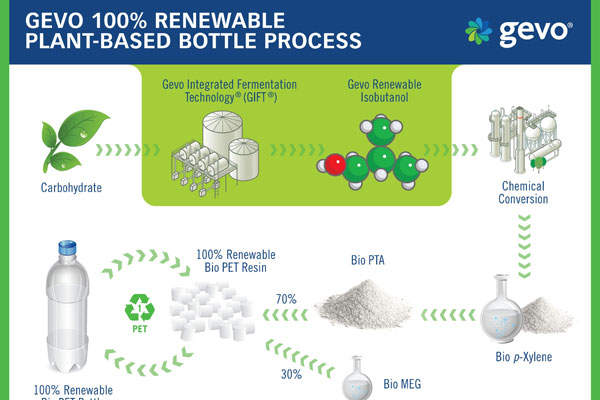

US-based renewable chemicals company Gevo produces paraxylene from bio-based isobutanol for Coca-Cola’s 100% bio-based PlantBottle PET resin under a similar agreement. A demonstration-scale paraxylene plant was also opened by Gevo in Silsbee, Texas, as part of the agreement.

Dutch research and technology company Avantium produces bio-based polyester polyethylene-furanoate (PEF), an analogue of PET, for Coca-Cola bottles using its chemical-catalytic technology platform YXY. The technology is used to derive PEF from carbohydrates containing biomass feedstock, such as sugarcane, agricultural residues, plants and grains.

A PEF pilot plant was opened by Avantium in Geleen, Netherlands, in December 2011. The agreement calls for commercial-scale PEF production by Avantium for Coca-Cola’s next-generation PlantBottle packaging.

The Coca-Cola Company, together with Ford Motor, Heinz and Procter & Gamble, announced the formation of the Plant PET Technology Collaborative in June 2012 as a strategic initiative to speed-up the development and use of rPET materials and fibre in their products. Heinz is already using Coca-Cola’s PlantBottle packaging technology for its ketchup bottles in the US and Canada.

Gevo’s Silsbee paraxylene plant in Texas

A demonstration-scale paraxylene plant was inaugurated by Gevo in Silsbee, Texas, in August 2013. The plant produces paraxylene for 100% renewable PET to be used in Coca-Cola’s beverage bottles. The plant converts bio-based isobutanol, a four-carbon fermentation alcohol, into paraxylene through chemical processes.

The paraxylene produced at the facility is used along with commercially available renewable MEG to produce fully-recyclable bio-based PET resin for Coca-Cola’s beverage bottles.

The paraxylene facility is located at Gevo’s existing jet fuel plant in Silsbee. Coca-Cola provided the R&D support for the plant under the Joint Development Agreement signed in 2011.

Japanese chemical company Toray is the other collaborator for the paraxylene plant. The Toray-Gevo collaboration had successfully produced fully renewable and recyclable PET from isobutanol at laboratory scale in 2011.

Toray provided funding assistance for the construction of the Silsbee facility. It purchases paraxylene from Gevo’s facility and converts it into PET fibres, textiles and films under an offtake agreement signed with Gevo.

Coca Cola’s sustainability objectives

Coca-Cola aims to use three million tonnes lesser virgin plastic from oil-based sources by 2025, which will reduce virgin plastic sourced from fossil fuels globally by about 20% and support the shared objective to be net zero carbon by 2050.

The company has committed to making 100% of its packaging recyclable, using recycled materials for 50% of its packaging, and collecting back the equivalent of every bottle it sells by 2030. This will prevent any of the company’s packaging from going to waste and allow old bottles to be recycled into new ones.

Related content

Coca-Cola Canning Line, United Kingdom

Coca-Cola Enterprises (CCE) in Milton Keynes is the company’s second-largest facility in the UK, with nine production lines.

Coca-Cola PlantBottle Spring Water Filling Plant, Johannesburg, South Africa

The Coca-Cola Company (Coca-Cola) unveiled a new water bottle filling plant in Heidelberg, in the Gauteng region of Johannesburg, South Africa, in July 2011.