BillerudKorsnas, a Sweden-based packaging manufacturing company, expanded its production facility in Gruvon with an investment of Sek5.7bn ($611m) in 2019.

The expansion helps in meeting the increasing demand for sustainable packaging solutions in the food and beverages industry across the globe.

Details of Gruvon facility expansion

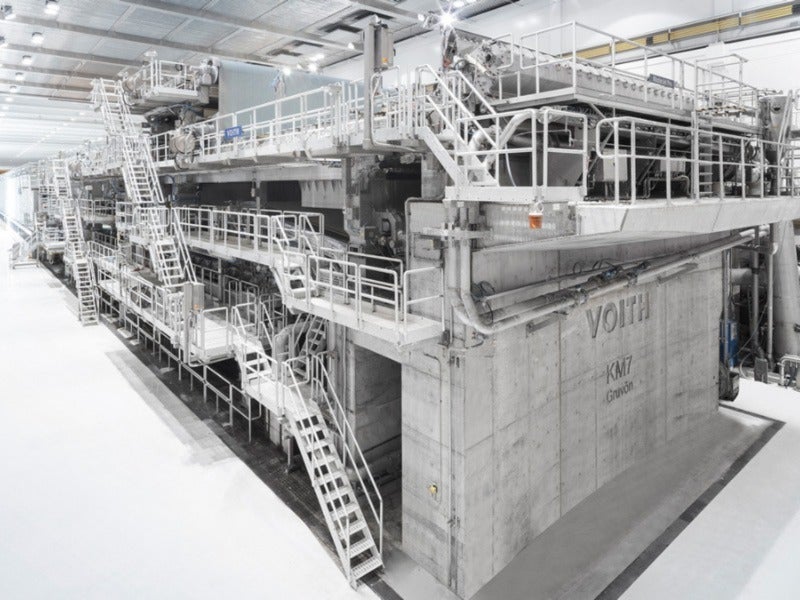

BillerudKorsnas’ Gruvon production facility was expanded with the installation of Voith’s XcelLine board machine BM 7 (KM 7), which is the most modern, efficient and largest board machine in the world. The project also included the reconstruction of the existing mill.

The new board machine came online in October 2019, which was followed by the shutdown of three older machines, PM1, PM2 and PM5, at the Gruvon facility.

The BM 7 board machine has a length of 350m and weighs 17,000t. It has a production capacity of 550,000t/year at a design speed of 1,200m/min and a web width of 8,800mm.

The machine is designed to produce liquid packaging board, white top kraftliner, carton board and cup stock used for milk cartons, fruit boxes, and quality cardboard boxes, such as boxes for perfumes, chocolates, and electronics.

The BM 7 machine is equipped with an advanced technological setup that allows the setting of new performance benchmarks for production lines for four different board grades.

The products manufactured in the machine will continue to support the reduction of the usage of fossil-based plastics in the world for several years into the future.

BM 7 board machine features

BM 7 board machine includes several state-of-the-art technological features and components. Its former section comprises a three-ply wire section with a DuoFormer D II hybrid former, two state-of-the-art DuoShake shakers and a fibre orientation control system. It also includes various MasterJet Pro F systems with additional IntraDamp modules for the headbox.

A Tandem NipcoFlex shoe press with SolarPress roll covers in the press section ensures optimum dewatering.

EvoDry steel cylinders are used in the dryer section of the board machine, which allows superior and safe paper drying by higher heat transfer and greater working width. The high-performance VariFlex XL winder is also a pioneering addition to the mill.

In the finishing section, the board machine is fitted with Curl Control. The machine has four different coating units, two SpeedSizer systems, a JetFlow F and a DynaCoat AT to maximise flexibility and optimise product quality. The SpeedSizer units and the DynaCoat AT feature carbon fibre supporting structures to ensure stable cross-machine direction (CD) profiles with consistent coating performance.

Monitoring and inspection system of BillerudKorsnas manufacturing facility

The Papermaking 4.0 solutions OnEfficiency and OnCare are the important components of the BM 7, which allow digital control of the paper production process. They help to monitor all process data and control them online in a user-friendly format.

Additionally, OnEfficiency Forming enables de-watering, retention and flocculation to be stabilised and coordinated at the same time. The OnCare package, including integrated asset management, ensures maximum machine availability, which helps to reduce project costs.

The facility uses the Procemex OnePlatform web monitoring and inspection system to enhance customers’ quality requirements. More than 150 cameras ensure the BM 7 product quality and production efficiency. The 44 web monitoring cameras along the board machine visualise root causes of web breaks and product defects.

Further, more than 100 cameras inspect the board machine in three different locations. The smart cameras process defect data and videos already inside their shell and all the defect information and their locations are transferred to a winding unit, which allows the operator to slow down or stop the winder from rejecting the defective part of the board.

The Gruvon facility features a development centre with expert knowledge of packaging optimisation.

Sustainable features

The smart packaging solutions manufactured in the facility are based on renewable materials, which are preferred due to their ability to limit the use of fossil fuels, reduce climate impact and littering, as well as increase food safety.

The wastewater from the new paperboard machine BM 7 is treated in a newly built treatment line of moving bed biofilm reactors (MBBR)-type.

Approximately 50% of the plant’s production is dedicated to liquid packaging board, while the remaining 50% includes folding boxboard, food service board and kraftliner.

Contractors involved

BillerudKorsnas contracted NCC, a construction and property development services provider, for the earth, foundation and concreting works for the production facility expansion in December 2016.

Sweco, a provider of consulting engineering and design services, was contracted for the construction management of the board machine and the structural design of the rebuild of the existing pulp mill.

AFRY (formerly AF Poyry), a provider of engineering and consulting services, was contracted to provide detailed engineering services for the board machine. The company was involved in the project since 2014, providing pre-project engineering services to convert the investment plan into a feasible technical concept.

In May 2017, Valmet, a developer and supplier of process technologies, was awarded a contract to deliver pulp dewatering equipment and an automatic pulper feed system.

Voith, a pulp and paper machine company based in Germany, delivered the BM 7 board machine, while Procemex, an electronics manufacturer based in Finland, supplied the OnePlatform web monitoring and inspection system to the facility.