In June 2007, Tetra Pak delivered the Tetra Gemina Aseptic carton packaging system to the Spanish fruit juice producer J García Carrión, which has used the new system to repackage and re-launch its premium Don Simón – Gran Selección freshly squeezed orange juice brand.

Tetra Pak designed the packaging system for dairy and beverage companies to adapt their products to changing market needs. In 2008, Tetra Pak launched the Tetra Gemina packaging system globally. after conducting nine consumer studies involving more than 1,500 consumers.

The studies were conducted between 2003 and 2008 across eight markets including Argentina, France, Germany, Italy, Russia, Spain, Canada and the UK.

The consumer studies revealed that the product packaging was perceived as contemporary, elegant and innovative.

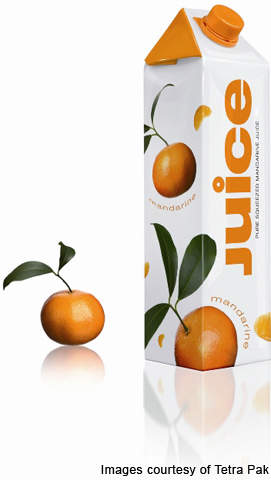

The unique shape, top and opening of the product enabled it to stand out on the shelf.

Tetra Gemina Aseptic

The system produces a roll-fed gable top carton, which has aseptic capability for all juice and dairy-based products such as liquid milk, drinking yoghurt and milkshakes.

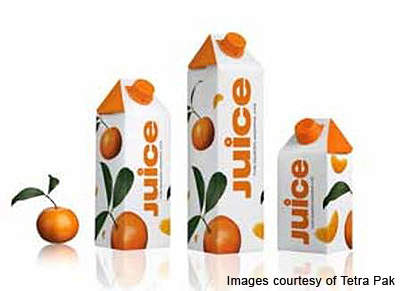

In October 2007, Tetra Pak extended the product range beyond its 1l size carton with the introduction of 500ml and 750ml cartons.

All Tetra Gemina Aseptic package sizes can be produced on a single Tetra Pak A3/Flex machine by installing a Quick-Change kit. A single machine operator carries out the packaging size changeovers. Around 85% of the A3/Flex machine’s components are identical to those in the standard machine version, except for the Twin Wheel Final Folder unit, which creates the unique ‘gabled’ top of the package.

By 2008, the company manufactured over 400 million Tetra Gemina packages. Most of the customer orders the company received, included the Quick-Change kit which enabled companies to respond to market changes and promotional opportunities.

Tetra Pack advantages

In 2006 over 130 billion individual Tetra Pak packages were produced by food processing companies, containing over 67 billion litres of products such as fruit juice and milk. The new Gemina Aseptic line was first unveiled at the 2006 Anuga exhibition in Germany.

The system also does not require refrigerated distribution which translates into lower distribution costs.

StreamCap

The StreamCap (made of polyethylene) has recently been incorporated across the range of Tetra Pak products, including the Tetra Pak Gemina Aseptic (also available in Tetra Brik Aseptic and Tetra Prisma Aseptic).

StreamCap is a screw cap, which can be opened in a single operation by the consumer and becomes extremely tight when closed. The closure system also includes a tamper ring to act as evidence to indicate when it has been opened. The closure provides functionality similar to that of bottles and uses less plastic compared to other closures which have membrane underneath the screw cap. The caps are available in a wide variety of colours to match the product the package is carrying.

In the converting process the hole for the closure is pre-punched with the aluminium and polyethylene remaining intact.

An advantage of this system is that the application of the StreamCap does not require a PullTab Unit to be fitted to the filling machine.

When the package is opened for the first time, a small set of plastic serrations cut through and then push aside the pre-laminated membrane making a reliable and clean opening.

StreamCap creates a hermetic and hygienic opening and resealing system that helps to preserve product freshness after opening. The opened and resealed carton can even be turned upside down and shaken without fear of leaks.