Edmonton-based Greys Paper Recycling Industries is building a unique recycling plant at the Edmonton Waste Management Centre in the Clover area of Edmonton, Canada. The new paper and glass recycling plant will have a capacity of 40Mt per day and annual capacity of 14,400Mt. Construction of the new facility commenced in October 2009.

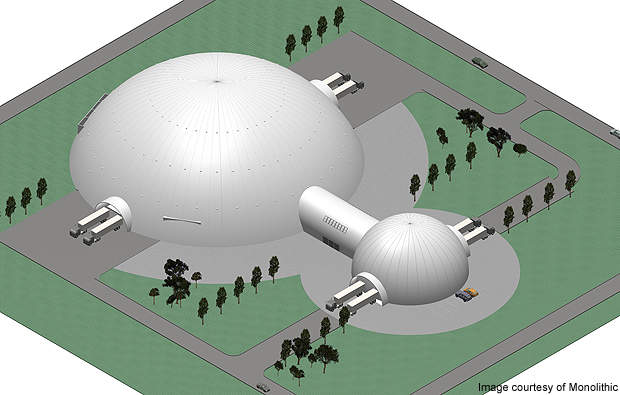

Recycling will be carried out in two energy-efficient industrial monolithic domes with built-up areas of 50,000ft² and 10,000ft². Construction of the bigger dome was in final stages in September 2010.

It will be 84ft high with a diameter of 252ft and will house the paper recycling plant. Both the domes will be connected by an 80ft long cylindrical office block with a diameter of 45ft.

Recycling will be carried out in two energy-efficient industrial monolithic domes with built-up areas of 50,000ft² and 10,000ft². The bigger dome is currently under construction.

It will be 84ft high with a diameter of 252ft and house the paper recycling plant. Both the domes will be connected by an 80ft long cylindrical office block with a diameter of 45ft.

Construction of the smaller dome began in April 2009 and was completed in May 2010. The smaller dome, which houses the glass recycling plant, is 54ft high with a diameter of 110ft. The glass recycling plant has already commenced operations. Waste glass will initially be pulverised at the plant and converted into sand to be used in the construction of the bigger dome.

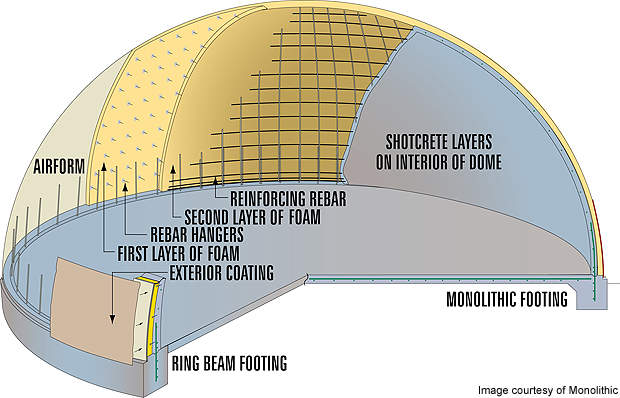

Several unique features have been incorporated in the facility to make it environmentally friendly. The domes will have R60 insulation to reduce energy consumption and increase efficiency.

They will use solar energy for daytime lighting for the plant and will be fitted with sun pipes.

The plant will use methane energy produced at other processing facilities at Edmonton Waste Management Centre for its heating.

It will use about one-twentieth of the water used by other recycling plants. This will be achieved by capturing rainwater and recycling water used in the plant’s processes.

Greys Paper closed loop process

The new plant will pioneer the closed-loop recycling concept in which recyclables are converted into similar products. The process reduces the amount of raw materials and energy required to convert waste into new products. It also reduces the total material volume lost as the waste is used repeatedly.

The conversion process at the paper recycling plant does not use any chemicals and can produce 100% recycled paper. The paper products gain additional strength due to the addition of cotton materials such as discarded bed-sheets and old cloth.

In addition, a natural resin is used to bind the different fibres in the waste material.

The recycled paper products produced using this process are grey in colour. Greys Paper can produce pure white paper depending upon the needs of customers. This is achieved in a natural way by adding recycled blue ink from old blue jeans.

The glass recycling plant will convert waste glass into various products such as ceramics and recycled glass tiles. Waste glass will also be converted into construction materials such as interlocking bricks.

These bricks can be used in landscaping and construction projects. The facility accepts all kinds of glass such as clear, coloured and mixed. The waste glass has to be sorted before it arrives at the plant.

Benefits

The new facility will help in converting all the waste paper collected from Edmonton into 100% recycled paper products. It will collect and process waste paper, cardboard, cloth and denim jeans on a daily basis. The plant will turn this waste into products such as writing paper, greeting cards, envelopes and carry bags. It will also produce paper-moulded products such as packaging boxes and cardboard trays.

Future plans

Greys Paper plans to expand and set up similar plants in Canada in the future. The company also plans to licence the technology to other companies. Greys Paper will expand its reach by awarding exclusive territorial licences to build recycling facilities in urban areas with at least 50,000 people. The technology will be adapted and modified according to the requirements of the location and country.