As part of Hood Packaging Corporation’s modernisation plans, the company invested in packaging machinery from Windmoeller & Hoelscher Corporation (W&H) in August 2005. Hood Packaging, based in Madison, Mississippi, is a major designer and manufacturer of packaging materials with a wide range of products including plastic film and bags, paper bags, and coated and laminated papers. The company is a key supplier of multiwall products in the North American market.

The investment in W&H range of equipment enabled Hood Packaging to modernise its equipment and offer its customers a diversified product range. Hood Packaging was able to corner a bigger North American market share and increase production efficiencies while lowering operational costs.

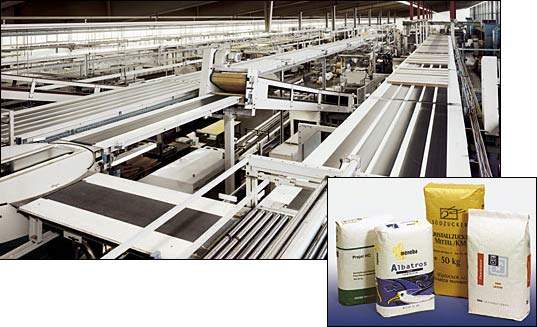

The machinery from W&H’s Multiwall Division included a PB®2555 pinch-bottomer, two AD®8310 bottomers, two Transystems® and two Arcomat®2 robot palletisers.

These were installed by early 2006 in the packaging company’s various plants around the US including Monticello, Grand Forks and Decatur.

PINCH-BOTTOMER

The new pinch-bottom equipment was installed in Hood’s multiwall converting facility in Hamlet, North Carolina. The plant has two completely automated pinch lines and the capability to tube, bottom and palletise pinch sacks in a single operation. The resulting bags now have mitred corners (flat bottom bag) with an ultrasonic seal with increased stability and a non-sift feature.

The AD 8310 bottomers were installed in Hood’s Pine Bluff, Arkansas, plant. The PB 2555 pinch bottomers with automated systems, multiple valve units and bottom patch capabilities have greatly enhanced the company’s productivity. The AD 8310 bottomer, which comes with Transystems automated material flow links, is a high performance, mid-range pasted-valve bottomer with an output of up to 300 sacks/minute.

The Arcomat 2 robotic palletising/automated stacking machines with automatic bag straighteners increased plant capability to over 25 cycles per minute and gave well-stacked pallets. There are also three stand-alone pinch bottomers over the two lines. This increased pinch bottoming capacity and automation has enhanced production capabilities at the Hamlet plant and allowed better quality.

PLASTIC SACK AND BAG-MAKING MACHINES

The PB 2555 pinch bottomer is capable of processing flat and side gusseted tubing into open-mouth pinch bottom sacks that have ultrasonically-sealed mitred corners.

The AD 8310 is a high performance, mid-range pasted-valve bottomer and comes with Transystems. The Transystems feature provides a logistic link to the various aspects of the multiwall production process. It performs heavy and repetitive tasks, is compactly made, and protects intermediate and finished products from damage caused during handling and transport.

Hood Packaging will be using Transystems as an add-on to the PB 2555 bottomers to feed sack packets to the Arcomat 2 robot palletiser. The palletiser had readily achieved its return on investment because of the improved stacking quality, which affected logistics and the sack-filling process. This automated production line increased packet frequency to more than 25 cycles per minute.

Hood’s decision to choose W&H’s equipment was based on several advantages of this machinery. The PB 2555 pinch-bottomer can processes up to 250 bags per minute when operating in-line with a tuber. There is also an option of fitting a feed section to the machine when operating off-line or with a turning/deviating station (when operating in-line with a tuber). The tube length ranges between 17.72in (450mm) and 51.18in (1,300mm) and the tube width between 7.87in (200mm) and 23.03in (585mm).

The PB 2555 machine incorporates an optional high-output, ultrasound mitred-corner sealing unit and has been designed for hot-melt and cold-glue applications. Sacks can also be sift-proofed with the heat-seal section.

A reject gate that sorts defective sacks was integrated into the PB 2555. It also has a special operating concept – an industrial PC with decentralised input/output and fibre-optic light bus communication – for trouble-free operation and comprehensive remote diagnostic service.

The AD 8310 can produce a variety of multiwall products. Its focus is primarily filling sacks (volumes of 4L to100L) including marketable paper sacks, which accounts for nearly 80% of multiwall production in the market. The automation has had major investment cost advantages and has not compromised on flexibility or the quality of sack configurations.

The AD 8310 valve bottomer was competitively priced and covered the entire range of standard multiwall applications. It features job changeover systems with adjustment differentials, positioning motors and automatic set-up tables.

It has a capacity and flexibility to handle different sack dimensions and constructions.

The machine has a high output – a maximum of 300 sacks per minute at volumes of 4L to 95L. The AD 8310 features optional kinematic tube-end opening when producing sacks with large bottoms and sophisticated sack constructions.

HOOD’S NEW LINES REDUCE COSTS AND PROTECT PRODUCTS FROM HANDLING DAMAGE

Hood Packaging’s production lines, incorporating the automated material flow systems and the robot palletiser and the bottomer, represents a highly efficient production system for the fully automatic paper sack production.

Transystems, the logistics machine, optimises the use of the bottomer and saves costs on personnel, reduces the capital tied up in intermediate products and protects intermediate and finished products from handling damages. Hood Packaging has leveraged the Transystems feature to make full use of existing production reserves and to optimise the cost structure of production.

NEW LAMINATOR

In June 2006 the Arden Hills, Minnesota facility introduced a new Nordmeccanica Super Simplex SL laminator. This is a solventless machine, which achieves lamination using a low-viscosity adhesive and a heated nip roller to achieve a strong bond between the layers. The solventless process is more environmentally friendly and also cheaper and easier to use with faster production.

The new laminator has doubled the laminating capacity of the facility. There are now two laminators at the facility including an older Dri-Tec water-based adhesives laminator and this means that Hood can provide for additional value-added plastic film packaging markets demanding different specifications.