The New Zealand-based glass packaging company Owens Illinois (O-I) unveiled a new glass furnace at its manufacturing plant in Penrose, Auckland in December 2010. The furnace has taken an investment of about $85m.

The Penrose plant was producing with two glass furnaces earlier. The new furnace is expected to increase the company’s glass packaging output by 90,000t a year. It will almost double the annual post-consumer glass recycling capacity from 84,000t to 154,000t resulting in less carbon emissions and wastage that goes to landfills.

O-I is the only manufacturer supplying glass packaging containers to the food and beverage industry in the region. Prior to commissioning the third furnace, the company had to purchase the recycled glass from a local recycling company Visy NZ.

The third furnace will help O-I to ensure steady supply of glass packaging material and reduce the lead times and freight charges to consumers. It has also created 38 new jobs increasing the total number of employees at the facility to 230.

Process

A batch mixture that consists of raw materials including sand, limestone, soda ash and recycled glass or cullet is mixed and melted in the furnace at 1,565oC. The molten glass is removed from the furnace and cooled to a uniform temperature.

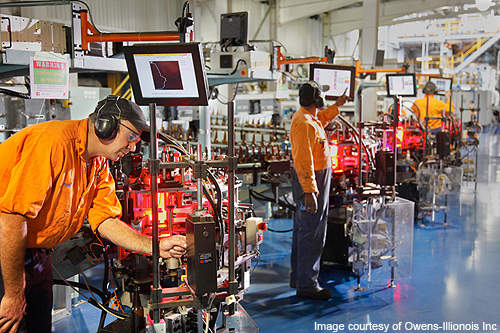

Gobs are cut out to form a glass container. The shape of the bottle depends on the gob cut out. These gobs are loaded onto forming machines known as individual sections (IS) where they are moulded as per the required container design.

The IS machine has a bank of 15-20 identical sections. Each section has a complete set of mechanisms to make containers.

The gobs are fed into each section through a moving chute called a gob distributor. The gobs are cut using shears and filled in blank moulds.

The formed containers are passed through a Lehr where they are re-heated and cooled in controlled temperatures to remove any impurities or stress. This process is called conditioning; it strengthens the glass bottles and prevents breakage.

The containers are finally inspected either individually or through computer control mechanisms to ensure quality. Any rejected containers are re-melted as cullet and re-used in the manufacture of glass packaging containers.

Technology

The new furnace at O-I uses narrow press and blow technology to manufacture glass. This technology reduces the bottle weight while maintaining the proportion and design.

Powered by natural gas, the narrow press and blow technology consumes less energy. This method is used in the manufacture of glass jars and very narrow neck bottles.

Using the technology, a parison (unshaped mass of glass) with a long metal plunger which presses the glass out into the baffle is produced. The baffle has rings and moulds that give shape to the parison./

The moulded container is taken out of the baffle and held over the dead-plate where it is cooled and sent on to the conveyors for annealing.

Annealing is a process by which the glass containers are reheated at 580oC and then gradually cooled over a 20-6,000 minute period depending on the thickness required. It removes the stress caused in the glass due to uneven cooling in the moulding stage.

Background

O-I was established in 1903 as Owens Bottle Company by Michael J Owens, the inventor of the automatic bottle making machine. It is the first company to manufacture glass bottles and jars of uniform height, shape and capacity.

The Owens Bottle Company was merged with Illinois Glass Company in 1929 to form Owens-Illinois Inc. It is headquartered in Perrysburg, Ohio and has a presence in Asia Pacific, Europe, Latin America and North America. Owens-Illinois holds the credit of being the largest manufacturer of glass containers in the world.