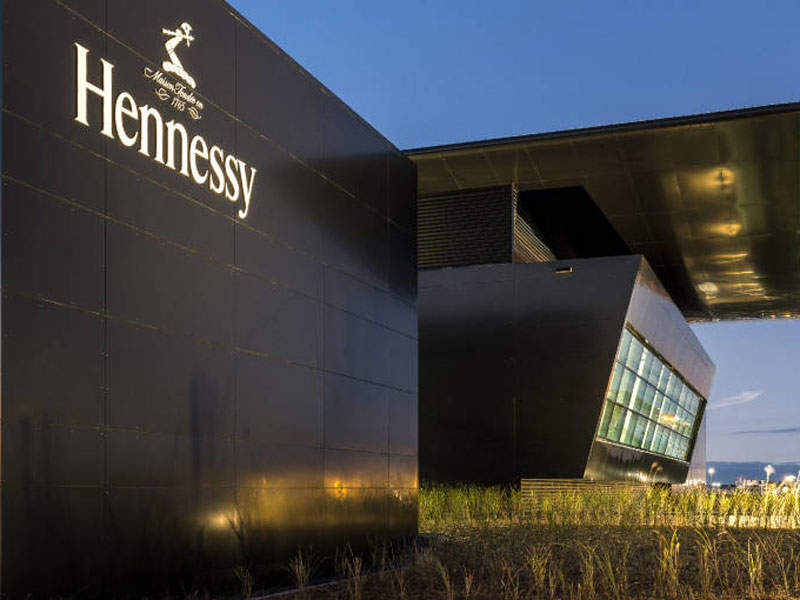

French luxury brands group LVMH’s wines and spirits division Hennessy inaugurated its new Pont Neuf cognacs bottling and logistics facility in Cognac, France, in October 2017.

The plant is located in Salles d’Angles commune in southwestern France.

The company unveiled its plan to construct the Pont Neuf bottling facility in May 2013. Preliminary assessments of the facility were carried out for a period of two years and the ground-breaking ceremony was held in September 2015. The construction involved approximately 200 companies.

Built with a €100m ($117.6m) investment, the bottling plant is expected to strengthen the company’s position in the global wines and spirits sector, as well as support regional economic development.

The facility created 70 new jobs during the construction phase and will further generate 110 jobs.

Production at Pont Neuf bottling and logistics facility

Hennessy’s Pont Neuf plant is the second bottling and logistics facility built by the company in Cognac, while the other facility was established in La Vignerie.

The Pont Neuf bottling plant is located on a 30ha site and has a 26,000m² footprint. It incorporates a high-speed bottling line, advanced packaging equipment and sophisticated traceability systems for packaging and distribution of cognac brandy.

The facility is capable of producing 240,000 cognacs bottles a day that paves way for increasing Hennessy’s production capacity to ten million cases a year by 2018 to meet growing demand.

Each step in the bottling process is tested before validation of cognacs by the Hennessy Tasting Committee and Master Assembler.

Sustainability features of Pont Neuf bottling plant

Hennessy’s new packaging and logistics unit is a two-storey building designed by Sandrolini Architecte. It is built to comply with green building standards to ensure sustainable packaging. The plant is equipped to recycle 92% of the waste produced on-site.

A rainwater harvesting system is installed to help meet the plant’s water needs. An optimised temperature control system is installed for improved temperature distribution. LED lighting and natural skylights are used to reduce the energy consumption by up to 50%.

Glazed and open spaces are designed to optimise acoustic quality. The algae paints, natural skylights and soundproofing will create comfortable work conditions for employees by providing improved air quality.

Low-carbon materials were used in the construction of the facility to further improve the environmental footprint by reducing carbon emissions.

The Pont Neuf bottling and logistics facility earned High Quality Environmental (HQE) certification by meeting all the stringent requirements set by Certivea.

Marketing commentary on Hennessy

Founded in 1765 and currently owned by LVMH (66%) and Diageo (34%), Hennessy is engaged in producing and distributing cognac brandy.

With headquarters in Cognac, France, Hennessy distributes its products to more than 130 countries worldwide. More than 99% of the company’s total production is exported to the global wines and spirits market.

As one of the leading distributor of French brand of wines and spirits, Hennessy is a major contributor to the country’s economy.

The company distributed more than six million cases in 2015.