Keeping pharmaceutical products secure from young children while still allowing the packaging to be accessible to older people who may have dexterity problems has always posed a problem.

Stora Enso solved the dilemma with a new type of drug packaging. Pharma SHR (Small Hands Resistant) is a reclosable carton ideal for highly toxic drugs, which require a high level of child safety while being very easy for senior adults to use.

Stora Enso Pharma SHR is a jointly developed packaging solution, with Bosch Packaging providing machinery and worldwide service.

Pharma SHR uses a new speciality tear-resistant cartonboard, CKB Pharma TR produced by Stora Enso. The European ISO (ISO 8317) requirements are exceeded by this board as it has exceptionally high tear resistance. In the US, Pharma SHR has been tested with the highest F=1 rating.

Contract packaging

In June 2006, the healthcare contract packaging company Testpak started producing the prize winning Stora Enso child-resistant and senior friendly packaging. Pharma SHR was a winner in the Apotek 2004 pharmaceutical packaging competition in Sweden and also the Verpackungswettbewerb 2004 in Germany.

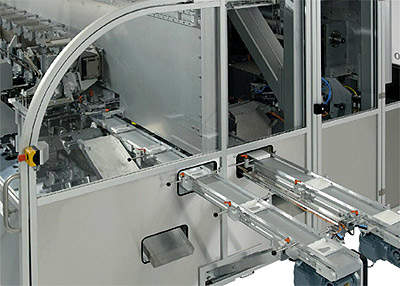

The first production machine was installed at the TestPak facilities in Whippany, New Jersey, US. The machine (SHR CSI 2035) was a flexible semi-automatic machine supplied by Bosch Packaging Technology with a variety of packaging configuration options. The new line (fully validated by the FDA) was the first to use Stora Enso’s Pharma SHR packaging system.

Stora Enso supplied the tear-resistant paperboard material as flat carton blanks, while Testpak filled the blisters in its existing packaging lines and also provided carton erection using the dedicated equipment from Bosch Packaging. Testpak started to provide SHR cartons to various pharmaceutical companies at the start of 2007 in developmental quantities for prescription applications.

Pharma SHR machine options

The semi-automatic and fully automatic Pharma SHR packaging machines can be installed as standalone, flexible units or integrated with a complete blister, vial or syringe line. Integration with existing machinery is also possible. The Pharma SHR solution is particularly suitable for packaging almost any existing blister in a child resistant way, without modifications to the blister.

Empty packages are delivered as flat blanks to the packaging facility, which reduces logistics costs and saves storage space.

Pharma SHR is ideal for unit-dose packages such as blister cards but can also be used for ampoules, vials, syringes and pouches.

With full F=1 child-resistant performance, the package developers now have an unprecedented degree of design flexibility with the internal contents. As a result, there are major benefits for user-friendliness, cost, tooling, development lead-time and platform consistency.

Market appeal

The market for smart pharma packaging is expected to grow to $1.7bn (€1.3bn) by 2013 from the current $25m (2007 figure), as more and more equipment suppliers, material suppliers, technology providers, converters and printers come up with cost-friendly smart packaging solutions. Stora Enso see Pharma SHR as being applicable to a whole range of other areas and aim to apply the technology to other commercial products.

Dual-lock mechanism

The packaging consists of a two-piece reclosable carton with the blister packs contained inside. The outer sleeve can be easily printed with the required graphics, marketing information and instructions. The package may only be opened using two actions as there is an ingenious dual-lock mechanism.

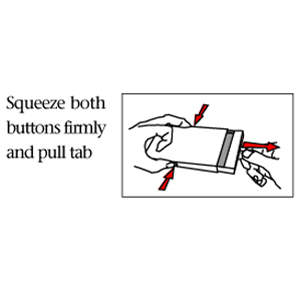

The sides of the carton have two round ‘cutouts’ (push buttons) allowing the inner tray to be pressured from both sides.

A tab at the opening end of the carton is attached to the inner tray.

To open, the two opposing sides of the carton have to be pressed gently on the ‘cutouts’ and the tab has to be pulled (squeeze and pull operation).

The tray will then slide out. The width of the design means that a child cannot grip around the package to operate the two ‘buttons’ while also pulling the tab at the same time, but because the adult grip or span is larger even an impaired grip can achieve access.

With the carton (secondary packaging) providing full child resistance, the primary packaging inside needs no further child resistance. There are also additional safety features including an anti-pry bar (prevents the package being broken open easily), moisture-resistance and ultrasonic sealing of the outer edges, which guarantees secure sealing.