Tuflex India is a division of Parry Enterprises India, part of the Chennai-based Murugappa Group. It was established in 1985 and is engaged in manufacturing a range of polymeshes, nets and knitted fabrics, and has a strong presence in sectors such as mosquito proofing, agro-shading, garden products, geotechnical engineering (soil reinforcement and stabilisation), net-based packaging and polymer-based products.

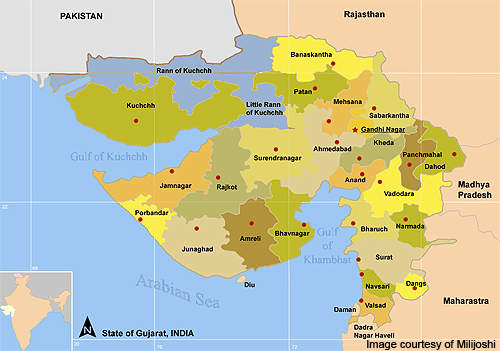

Tuflex India started the flexible packaging production facility at Palej in the state of Gujarat, India, in October 2008. The new unit is aimed at providing quality laminated structures for flexible packaging across industries such as food, pharmaceutical, lubricants and chemicals. Some of the standard packaging products manufactured at the unit include vegetable and toy nets, protective sleeves, shopping bags and soft sleeves for rose buds. They are available in different sizes of 1000m in length and 200mm-400mm width.

The company follows an aggressive growth strategy through innovations. Its packaging systems are already certified under the ISO 9001:2008 standards. The company is currently aiming for ISO 22000 (HACCP) certification. The new facility at Palej features a green field production facility of flexible printed laminates.

Equipment installed

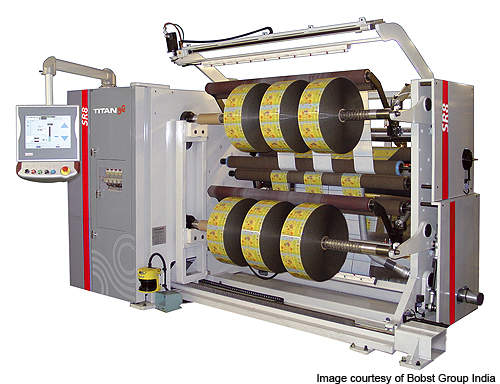

The packaging division has Bobst Group’s Rotomec RS 4003 gravure press platform and Titan SR8 slitter.

The RS 4003 installed at the Tuflex flexible packaging facility is a highly productive machine used for medium to long-term printed, flexible packaging materials. It provides compact and cost-effective packets for food and non-food products such as snacks, cereals, detergents, shampoos and pesticides.

The Titan SR8 twin shaft cantilever slits / rewinds a range of printed and laminated materials. The machine operates at a speed of 700mpm (2300fpm) and the slit widths can be below 25mm (1in).

Tuflex printers

The plant uses Gravure, a simple mechanical printing process. The ink from the inking system is transferred to the substrate through the printing cylinder, which has the image engraved on its surface.

As the cylinder rotates in the ink pan, the doctor blade wipes out the extra ink from the surface of the printing cylinder.

A rubber covered sleeve, mounted on the steel mandrel presses the substrate onto the printing cylinder resulting in ink transfer on the substrate.

The dryer dries the wet ink on the substrate before printing the next unit. The size of the dryer is determined based on the type of printing speed, ink types and volumes required. A chill roller at the exit point of the dryer ensures that the right temperature is maintained for the next print.

An automatic side and length register control system prints the colour as per the predetermined design of the package.

Packaging

The plant is installed with the TITAN SR8, an advanced slitter-rewinder machine of the TITAN SR series. It features the latest mechanical, hydraulic, pneumatic and electronic and computer control technology that provides an economic and simple packaging even during increased production levels.

The machine is available with standard features such as differential winding technology, AC digital servo drive, Fife digital line / edge guide system, unwind closed loop dual brake control, carbon fire idle roll construction, razor and rotary crush slitting.

The PC control, S-wrap centre drive, CE safety fencing, laser scanner, a range of unloading booms and remote diagnostics also form part of the standard features.

The optional features include fully programmable auto-knife positioning, dual motor driven unwind, digital knife positioning read-out, closed-loop loadcell rewind control, production monitor software package, impression counter, static eliminators, gap winding control and splice table.

The automatic knife positioning, laser core positioning, shaftless unwind technology and automatic slit unloading, facilitate quick and easy packaging, resulting in high productivity.

The two web configurations, integral unwind and free-standing unwind, provide the operator with ample working space and high automation levels.

The machine can slit and rewind in the width range of 1050mm (41″) to 1850mm (72″) with a diameter of 1300mm (51″). The machine can be used for plain film, printed film, paper, labelstock, laminations and metallised film packaging.