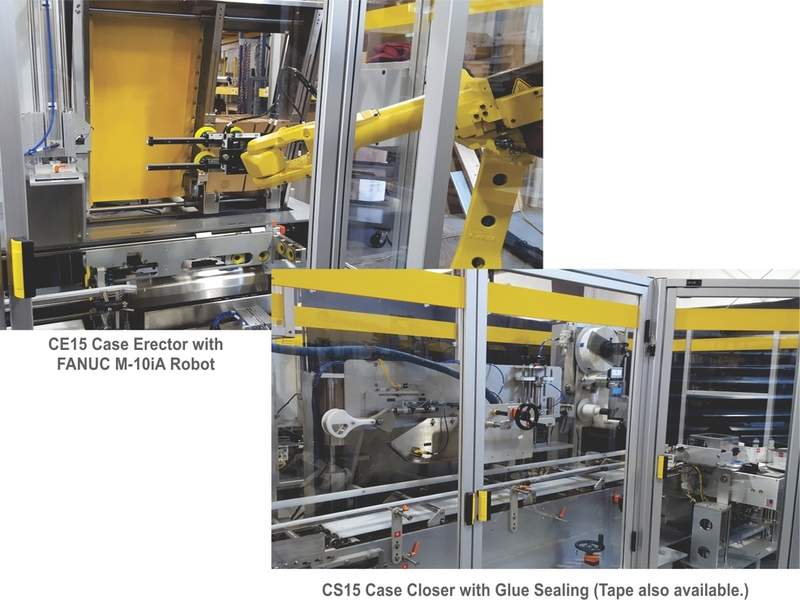

US manufacturer ESS Technologies has designed the new Model CE15 Robotic Case Erector and CS15 Modular Case Sealer that can integrate with existing case packing lines.

The machines will enable manufacturers to automate manual case erecting and closing processes in a limited factory floor space.

The newly designed CE15 / CS15 machines can be used to pack pharmaceuticals, nutraceuticals, cosmetics and consumer goods products.

Equipped with a FANUC M-10iA robot with custom, ESS-designed end-of-arm tooling (EOAT), the CE15 Robotic Case Erector is capable of producing up to 15 cases per minute.

The robot picks a case from case magazine to square the sides using the special EOAT and runs it across a bottom closer.

See Also:

Following this, the case is transported through the case conveyor to a manual or automated loading station.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataLater, the case will be transported to the CS15 Case Closer and Sealer module.

The CS15 can be integrated with the case loading systems, along with labellers, shrink wrappers, case check-weighers, and robotic palletising systems to develop a complete case packaging line.

Both systems use Allen Bradley controls and feature a colour touchscreen HMI.

ESS works with original equipment manufacturers (OEMs) to integrate coders, labellers and inspection systems to develop a solution for track-and-trace case packing applications.

The company has also installed multiple serialisation-enabled case packers in North America and provides shipment of serialised cartoners, case packers and robotic pallet cells within three to five months depending on the machine and application.

Image: CE15 Robotic Case Erector and CS15 Modular Case Sealer. Photo: courtesy of ESS Technologies.