Packaging equipment manufacturer Sidel has received the US Food and Drug Administration (FDA) approval for its Aseptic Combi Predis FMa blow fill seal filler.

Following the approval, the new PET filler can be used for low acid manufacturing and commercial distribution in the US market.

Sidel sensitive products director Guillaume Rolland said: “It confirms our Aseptic Combi Predis design is compliant with the FDA's current good manufacturing practice (cGMP) requirements.”

The Sidel aseptic solution can now produce and distribute shelf-stable low acid products in PET bottles across the US.

Dover Brook Associates (DBA), which was the Process Authority for the Sidel aseptic filler, validated the scheduled processes of the Aseptic Combi Predis using a scientific-based approach of specific tests and acceptance criteria.

See Also:

The results demonstrated that the scheduled processes were in compliance with the predicate rules and expectations of the FDA.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

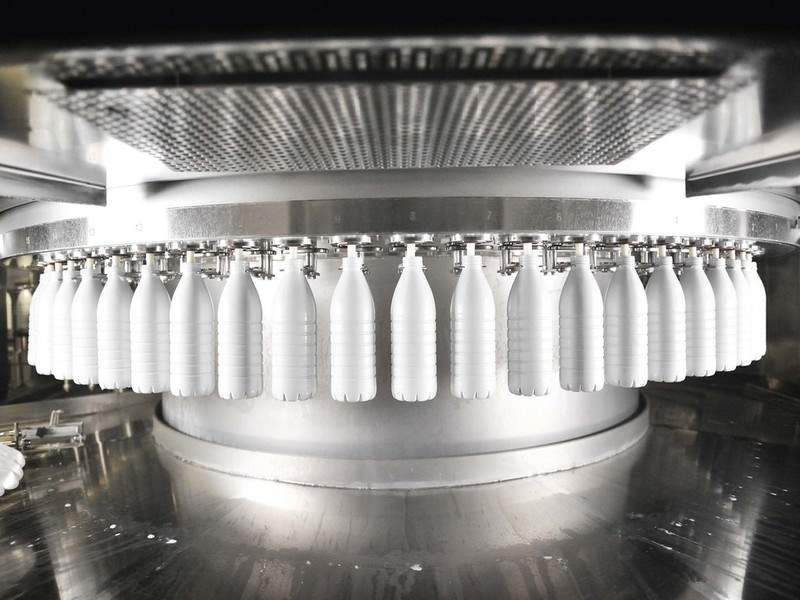

By GlobalDataThe Sidel Aseptic Combi Predis merges dry preform sterilisation with aseptic blowing, filling and sealing functions within a single production enclosure.

Sidel aseptic product and platform manager Arnaud Poupet said: "DBA's testing demonstrated that the sterile zone during the blowing process was the critical component, not the blow-moulding zone itself, which was due to the Sidel patented dry-preform sterilisation technology."

The company noted that the regulatory acceptance validates that the Sidel technology is completely safe for packing UHT milk, soymilk, coconut water, or teas in PET bottles.

Image: Milk Filling using Sidel products. Photo: courtesy of Sidel.