Glass bottles and containers manufacturer Altajir Glass Industries’ glass factory (Jebel Ali Container Glass Factory), located in the Jebel Ali industrial zone of Dubai, manufactures glass bottles with a daily output of 4.5 million units.

The facility underwent its first expansion in mid-2003 with an estimated investment of AED100m ($27.2m). This expansion included the installation of a third bottle production line in just 85 days. The new production line increased the facility’s production capacity from 1.5 million to 2.25 million bottles a day and added 540t/d of melting capacity.

The state-of-the-art facility has since continued an aggressive expansion programme based on increased demand for its products in the Middle East and worldwide. Overall demand across the gulf is 300,000 tons (t) a year, and 70% of the facility’s production is exported either to the gulf or elsewhere around the world.

Expansion details

The second phase of expansion began in late 2003 and was completed by late 2005. The investment for phase two was AED550m ($150m), taking the total investment in the plant since it was first constructed in 1996 to more than AED1.1bn ($300m).

The plant’s output capacity increased to 4.5 million bottles a day, and the new, expanded facilities allowed the plant to produce a wider range of bottles, including heavier bottles and wide-mouth food jars.

The expansion also included a new production line for manufacturing decorated refillable bottles. This additional line increased decorated bottle production capacity at the facility from 500,000 a day to more than one million.

Narrow neck press and blow technology

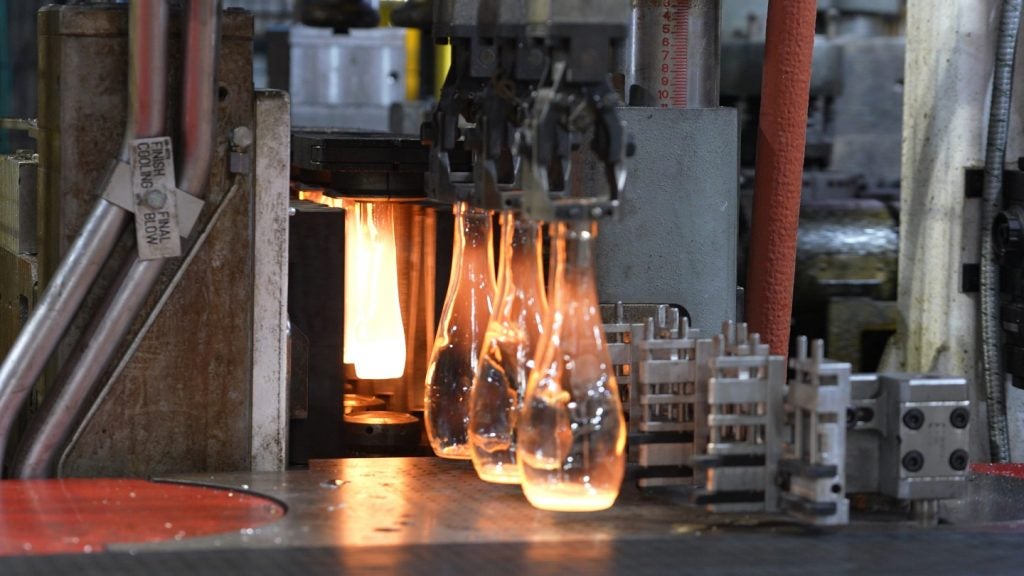

The facility uses narrow neck press and blow (NNPB) technology, which allows bottles to be made much lighter and with up to 25% less glass in each container, therefore saving on the cost of materials. It also allows glass containers to be made with much higher accuracy, resulting in fewer defects on internal surfaces and a lower rejection rate. Furthermore, the lighter-weight NNPB-made bottles are stronger due to better glass distribution.

The technology uses a metal plunger to form the internal cavity in the bottle during blank formation, instead of the air bubble used in older methods. The gob enters the mould at a temperature of 1,200°C, the mould closes, and the plunger, driven by a pneumatic piston, pushes the molten glass all the way into the mould. The plunger then withdraws, and the mould opens, releasing the blank to move onto the next stage of production.

Ventilation

In 2005, the glass plant had a problem with its main ridge ventilator, located above the melt furnaces. This ventilator was not allowing sufficient heat to escape, and the wind was causing a backdraft problem. Bradford Ventilation, a CSR Bradford company, provided and installed 16 H900 Hurricane™ turbine ventilators, with eight installed on either side of the large ridge vent. The situation improved markedly after this installation. Al Mutaiwie-Barrie Harmsworth served as a consultant for the installation.

Construction and contractors involved

The construction of the building expansion – including steel construction, cladding, general construction, and electrical and mechanical engineering – was awarded to various companies in Dubai.

Engineering consultants included project management consultancy services provider Al Nibras Management, engineering consultancy firm ECG Engineering Consultants Group, and structural engineering consultant Veth Consultants.

General construction was carried out by building contractor Al Ummah Contracting, while Yerevan Steel Construction Company, a steel fabrication company, erected the steel superstructure of the expansion building.

Al Shirawi Electrical and Mechanical Engineering Company, an electrical and mechanical services company, installed the necessary electrical and utility infrastructure.

US-based Owens Brockway Glass Containers was retained as an advisor, as they were responsible for outfitting the original plant in 1996.

Italian company All Glass provided some moulding equipment for one of the three new manufacturing lines.

Super Furnace Works of India constructed two new energy-efficient vertical loading electric arc furnaces, with an easy maintenance facility, each with a production capacity of 250t.

Germany-based Zippe Industrieanlagen provided cullet preparation and batch-processing equipment to produce raw materials for the furnaces.

Siemens Energy and Automation were involved in the installation of electrical power plants to run the furnaces. Horn Glassanlagen, based in Germany, supplied some moulding equipment for the smaller-volume glass containers, while US-based Struts provided equipment for the decorated bottle facility.

Nils and Abbas Trading from Dubai provided the compressed air systems for the bottle-blowing lines. Another Dubai-based company, Computer Network Systems, provided the IT infrastructure for the new expansion.

AGR International from the US provided inspection and integrity testing equipment to test bottles produced at the new plant for quality. Kawasaki provided the palletising equipment for the packaging end of the facility.

Swiss company Emhart Glass provided three 340 Forehearth systems (200t capacity), temperature monitoring systems, gob forming systems, container forming systems (three IS 6 1/4 machines, 12 section triple gob, capable of producing bottles at a rate of 200 per minute), hot-end equipment, cold-end equipment and networked control systems for the facility.

State-of-the-art control systems to precisely monitor temperature along the entire manufacturing process, therefore ensuring optimum production conditions from melt to final bottle, were also developed by Emhart Glass.

EV Cargo logistics group unit Jigsaw secured a contract to import and distribute glass bottles from the facility to the UK. A fully managed integrated solution across Jigsaw, Allport Cargo Services (ACS) and CM Downton supplies around 200 containers of glass bottles to the UK from the Altajir glass bottle manufacturing facility each month.

The contract helps to address a shortage of glass bottles in the UK by enabling the development of a new supply chain flow and providing a robust solution.

According to the agreement, containers arrive into Bristol, Southampton and Felixstowe ports, where ACS manages customs clearance and transportation to warehouses. CM Downton controls the storage at its strategically located warehouse facilities, and Jigsaw manages the transport to customer sites.