Russia is a much more sophisticated market for food and beverage products than it used to be; over the last 20 years a number of companies have moved into Russia to provide items that were not available before.

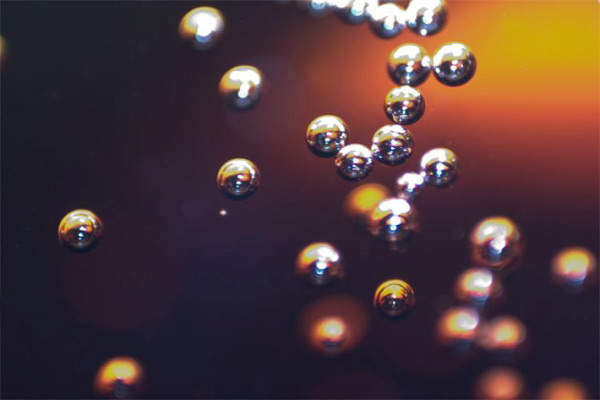

The South of Russia, near the border with Turkey in the Black Sea and North Caucasus regions, is a vast market for beer, wine and mineral water. However, a plentiful supply of bottles is required for production and there is very little bottle production in the region, which has only 4% of the glass container production capacity of Russia.

Consequently, a well-known Turkish company, Turkiye Sise ve Cam Fabrikalari (SiseCam Group), built a new bottle plant on a greenfield site in Krasnodar, Russia. Commissioned in May 2009, the Krasnodar plant is being operated by a new company, Ruscam-Kuban, which is a majority-owned subsidiary of Anadolu Cam, a member of SiseCam Group.

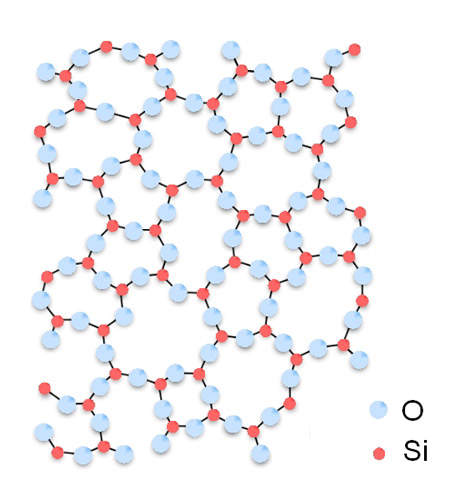

Glass economy

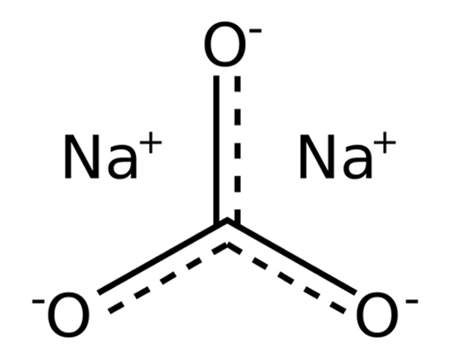

The plant had an immediate twin effect on the economy of the region. Firstly, suppliers for the quality materials for glass production such as soda ash and sand needed to be sourced. SiseCam is aware that it needs to educate local suppliers as to the quality required. Secondly, the wine – producing sector is centred in Krasnodar and is growing at a rate of 10–15% per year. The plant is therefore in a position to provide bottles for the sector, focusing on sparkling wine producers in the Central Volga region.

In addition, the mineral water production of Russia is very much concentrated in the south of the country, from the mineral water sources in North Caucasus, and the new bottle plant will also be able to provide bottles for this.

The plant is situated in Krymsk, about 40km from the Black Sea port of Novorossiysk and employs 450 people. The capacity of the plant is around 240,000 bottles a year. The company’s five existing bottle plants in Russia produce more than one million tonnes of glass packaging annually through ten furnaces.

Construction

The Krasnodar Glass Packaging Plant was built using part funding from the European Bank for Reconstruction and Development (EBRDA) amounting to around €52.5m. This was announced in April 2008. The total investment on the plant approached a figure of €75m.

The plant was constructed in two phases with an initial capacity with one furnace of 140,000t per annum. A future phase will see production doubled to 280,000t per year when a second furnace is constructed. The bottle production is based on narrow-neck-press and blow technology (NNPB), which uses around 20% less material than conventional production, has less breakages and allows a faster production cycle. The plant was constructed by Saint Gobain of France using state-of-the-art technology.

Technology

Operated by Anadolu Cam, the Krasnador plant uses latest technology in production process. All the production lines are equipped with automatic container inspection equipment that sorts the material. In addition, every stage of production including batch production and furnace operation is computer controlled.

EBRD finance

The EBRD finance initially provided will be €37.5m (debt, seven-year loan), in two lots which will be timed to match the investment for each furnace. The two sums will be initially €26.3m (phase one) and then later €11.2m (phase two). In addition, the EBRD will provide €15m of an equity investment into the company as it is a new special purpose vehicle (SPV).