BERHALTER specialises in the manufacturing of user-friendly and highly productive die-cutting machines. Die-cutting is part of the complete supply chain of a final product and has a big impact on the product’s success. What die-cutting solution you choose decides on the appearance of the product, its sustainability, quality and efficiency.

As the industry develops and provides increasing market demands, BERHALTER has reacted continuously and with flexibility by introducing a number of innovations to the market. In addition to its constant innovations, BERHALTER is synonymous with the production of efficient and customer-oriented die-cutting systems.

BERHALTER meets the challenges of the markets through close cooperation with its customers. We are more focused than ever on customer and production needs and are dedicated to using our experience to find the right die-cutting solution for each application.

High-performance die-cutting machines

BERHALTER is the world’s only manufacturer of flatbed die-cutting machines with its own tool-making shop. We assist customers as highly professional and responsible partners for the complete die-cutting process. As both a leading manufacturer of high-performance die-cutting machines and a specialist in die-cutting tools, we offer tailor-made services that are 100% made in Switzerland.

With BERHALTER die-cutting systems, the range of applications is endless, allowing both the intricate lid and label geometries.

IIoT platform for monitoring productivity and efficiency of die-cutting machines

CUTcontrol creates the infrastructure for collecting and managing data streams. These data streams come from machines, machine options and tools. Our CUTcontrol takes on the role of a support system and uses diagnostic tools for data analysis. With the use of dashboards, data can easily be converted into valuable information.

Our CUTcontrol is characterised by a smart connection, integration and applicability with the overview of machinery and its performance.

CUTcontrol offers a particularly high economic benefit for the customer. CUTcontrol guarantees the most modern communication with BERHALTER systems worldwide. It offers all functions for monitoring machine and tool status: from OEE and error detection/handling to notification and data analysis.

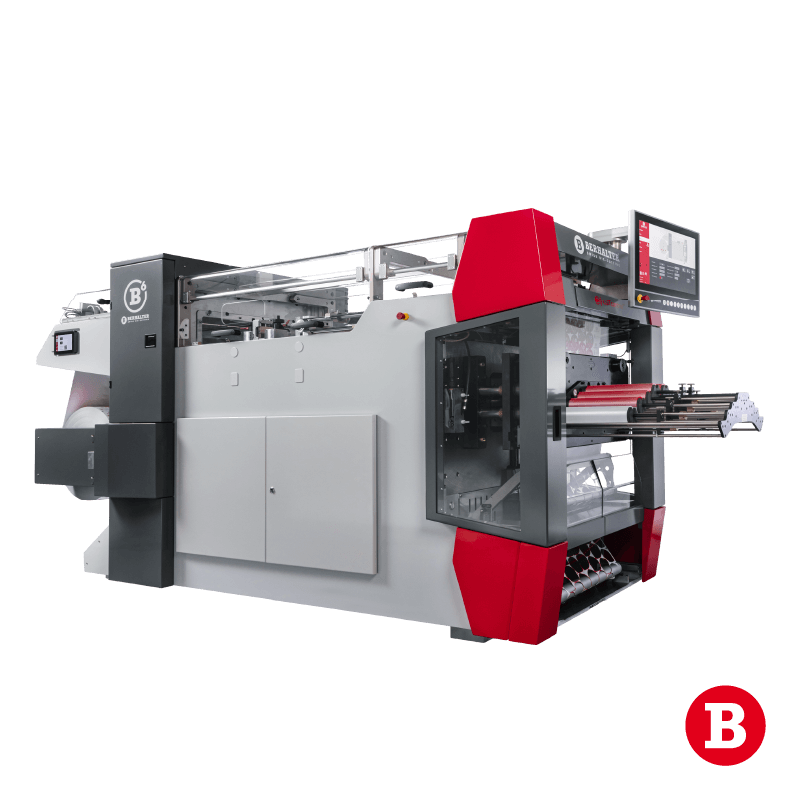

A portfolio of innovative, dynamic and intelligent die-cutting machines

With a web width of up to 600 mm, the new Berhalter Swiss Die-Cutter™ B6 makes a strong statement in terms of technology and modernity. Operating at 500 strokes per minute, the model embodies the DNA of all BERHALTER high-performance die-cutting machines, which are innovative, dynamic and intelligent. The Swiss Die-Cutter B4 has the same performance but is designed for a web width of up to 430mm.

BERHALTER’s high-performance die-cutting machine Swiss Die-Cutter™ B4 and B6 are characterised by high levels of flexibility to enable a wide range of applications. With up to 500 strokes per minute, these high-performance flatbed die-cutting systems are used for medium and higher runs.

The Swiss Die-Cutter™ is revolutionizing the flexible packaging industry with its high performance! With automation, robotics and IIoT technologies, it enables medium to higher runs, including lids, labels and specialty products.

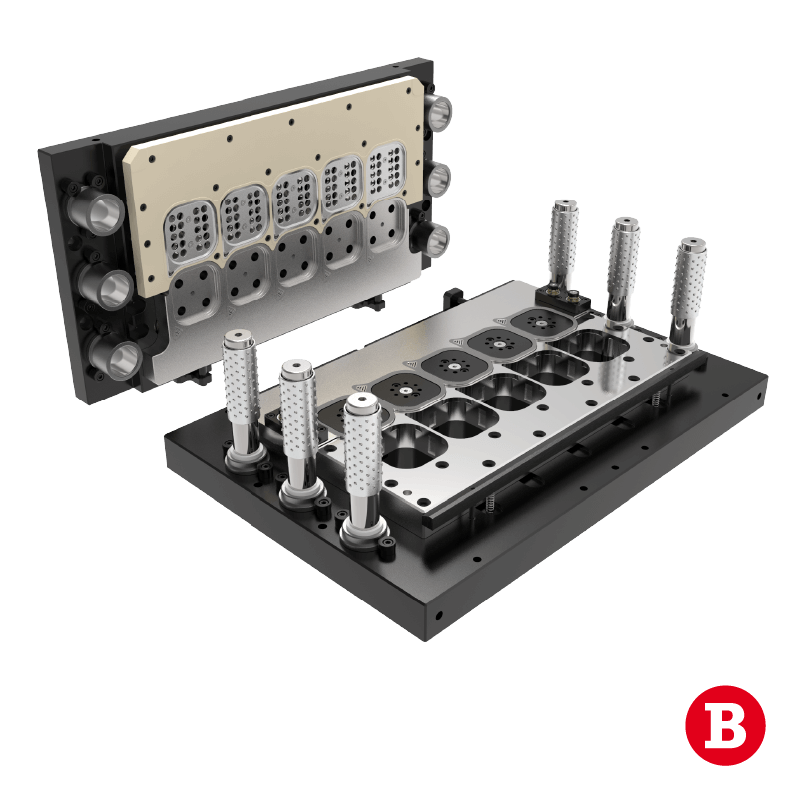

Swiss Die™ – Die-cutting tools

BERHALTER also supplies high-precision and high-quality die-cutting tools for the highest demands, high productivity and flexible applications. Powerful cutting components with a long service life for increased efficiency, as well as innovative tool solutions for demanding products, harmonise perfectly with the die-cutting process.

Swiss Die PRO™ & ULTIMATE™

High-precision die-cutting tools for small to large production volumes. Suitable for the processing of simple to demanding materials. The highlight is the highly wear-resistant cutting components for maximum durability up to 80 million strokes.

- Material: aluminium, plastic, paper, composite material

- Application: flat lids, recessed lids, labels, in mold labels (IML), blow mold labels, seals, technical applications

- Machines: B350, B500, B4, B6

Swiss Die LABEL-light™

High-quality die-cutting tools for small to medium production volumes. Suitable for processing simple geometries and corners with a radius R of 0mm. The highlight is the adjustable cutting components for flexible size adjustment up to 2mm.

- Material: plastic, paper

- Application: flat lids, labels, in mold labels (IML), blow mold labels

- Machines: B350, B500, B4, B6

Swiss Die ECO™

High-value die-cutting tools for small to medium production volumes or qualification runs. Usable for Swiss Die PRO™ & ULTIMATE™ and Swiss Die LABEL-light™. The highlight is a tool frame that is suitable for all types of die-cutting tools.

- Material: aluminium, plastic, paper, composite material

- Application: flat lids, recessed lids, labels, in mold lables (IML), blow mold labels, seals, technical applications

- Machines: B350, B500, B4, B6

Tools for sampling and qualification runs

- Up to 500 lids or labels – Swiss Die START™

- Up to 5,000 lids or labels – Swiss Die FLEX™

- Up to 200,000 lids or labels – Swiss Die VARIO™

BEAMstack™ packaging systems and robotics

Implementing intelligent and operator-friendly packaging solutions is guaranteed to increase productivity. This includes always having the ideal stacking channel with the right packing aid for the most efficient handling of die-cut stacks. BERHALTER considers the integration of packaging systems to be a holistic task and also develops individual solutions perfectly tailored to different packaging requirements. Whether standard stacking channels or automatic packaging solutions are desired, BERHALTER customers are able to choose the right level of efficiency for their production.