O-I (in April 2005 Owens-Illinois changed their name and began trading as O-I), one of the largest manufacturers of glass containers in the world, announced in September 2003 the start of construction of a new bottle manufacturing plant in Windsor, Northern Colorado, the US.

This is the first new US glass container plant to be built in nearly 25 years. The company invested $140m to design, construct and fit out the new facility to supply glass bottles to local breweries.

Owens-Illinois already operates 25 glass container manufacturing plants in North America, but the new Windsor facility will now be the largest of its plants so far. The 90-acre site houses a plant with a floor space of 550,000ft², which contains the latest Owens-Illinois patented machines and glass technology.

O-I facility siting and construction

The plans to build this facility were first announced in February 2003; the company then considered 16 different sites before deciding in favour of Windsor in Weld County, Colorado. However, the site chosen for the plant was not without its problems.

Company engineers discovered that the water table in the area they intend to develop was close to the surface and water could seep into the lower areas of the building. This was solved by building a slurry wall, a ditch that goes 30ft to 40ft below the ground and keeps ground water from spilling into the site.

Construction and development corporation Hall-Irwin, based in Greeley, Colorado carried out the slurry wall construction work at the end of 2003.

The architects who designed the facility were Albert Kahn Associates, Inc. Turner Industrial provided the design / build construction services for the facility. Precision Erection Company, Inc. (PEC) were contracted to install steel and panels. The scope of the work included design and construction of all site, facility and process support systems along with management of owner installation contracts for all of the processes.

The project also included conventional steel construction for two oxygen fuel furnaces with four 12-quad bottling machines. The project also involved the installation of inspection and packaging equipment along with warehousing operations in pre-engineered metal buildings attached to the conventional steel structures.

Other buildings included systems rooms, mould machine repair, general stores and administration. A 170ft tall batch house was also constructed for raw material storage and mixing. The building was completed by the end of 2005 with the plant starting up for commissioning, while production started in February 2006.

The new bottle manufacturing plant has brought much needed employment to the area. The company created 200 new jobs in Colorado.

Of these 200 new jobs, 170 were on the manufacturing side and pay in excess of $40,000 a year. These high-paying jobs are a great boost to Northern Colorado economy.

O-I bottling facility start up

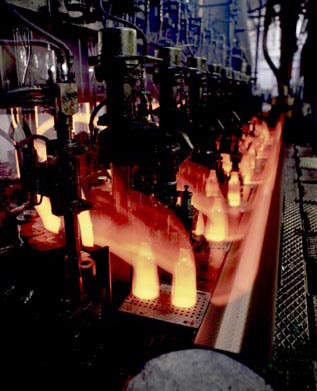

O-I fired up the furnaces at the new plant in autumn 2005. The new plant is a state-of-the-art manufacturing facility and O-I used the best in technology from its plants around the world in the plant, which produces in excess of three million 12oz beer bottles a day for the nearby Anheuser-Busch filling plant north of Fort Collins (full capacity is one billion bottles per year).

The plant runs on natural gas and the forming and inspection machinery, including the single largest glass-forming machines in the world, was manufactured by O-I using proprietary technology.

Funding

Owens-Illinois was given an economic incentive package totalling about $4m for the construction of the Windsor plant. This package includes a $500,000 performance-based grant from the state of Colorado, which is given to the company for creating new jobs.

In addition, the state provided a Community Development Block Grant of more than $770,000 to help fund infrastructure at the site and about $60,000 in job training.

Glass manufacturing

The first completely automatic glass bottle blowing machine was invented in 1903. This machine made it possible to mass-produce bottles and jars of uniform height, weight and capacity. High-speed filling and packing lines soon followed.

Glass containers entered the modern age, with today’s machines capable of producing over one million bottles a day.

The glass container manufacturing process involves a range of procedures, equipment and materials. The following list follows the procedure for the manufacture of glass containers:

- Glass melting

- Container forming

- Container conditioning

- Surface treatment

- Automatic inspection

- Product handling and packaging

O-I bottle identification

Owens-Illinois glass containers are individually stamped to enable identification. Information is located either on the heel (rounded side bottom) or on the bottom of the bottle. There are three main points to note:

- Plant of manufacture

- Owens-Illinois mark

- Year of manufacture

O-I

O-I is the largest manufacturer of glass containers in North America, South America and Australasia. O-I has made some changes in 2005, aside from changing the company’s name, resulting from the acquisition of BSN Glasspack and the subsequent sale of the Company’s blow-moulded plastic container business.

Retaining a niche plastics presence in healthcare packaging and specialty closure systems, O-I’s offering is now 88% glass packaging with more than 60% of its revenue base coming from outside of the US. The company has also established a European headquarters in Lausanne, Switzerland.