Pakistan-based packaging printing company Rehmpack has selected Koenig & Bauer’s latest, high-performance sheetfed offset technology to be deployed at its newly built facility in the Port Qasim Industrial Area, one of the two seaports in Karachi.

Koenig & Bauer is a Germany-based sheetfed offset press manufacturer for packaging applications.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The new 200,000ft² Karachi facility is scheduled to be operational next year.

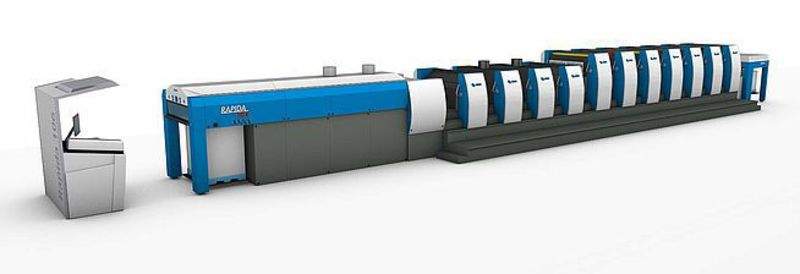

The Rehmpack facility will be equipped with a latest seven-colour Rapida 106 system in a double-coater configuration for ultraviolet (UV) and conventional printing.

Featuring 11 printing and finishing units, the new sheetfed offset technology will be Rehmpack’s first Rapida press and is slated to be delivered at the end of the year.

Rehmpack director Atif Anis Barry said: “When making our decision, we paid particular attention to efficient, future-oriented technologies and high-print quality.”

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataRapida 106’s double coating process will help expand the product portfolio in respect of high-quality finishing.

The Koenig & Bauer press features a DriveTronic Simultaneous Plate Change (SPC), DriveTronic Plate Ident, CleanTronic washing systems, DriveTronic Simultaneous Forme. Change (SFC) coater with AniloxLoader, and kit for mixed operation with conventional and UV inks.

Rehmpack’s current list of customers includes several major brand names such as Procter & Gamble, GSK, Colgate-Palmolive, Mondelez, Coca-Cola, English Biscuits, Continental Biscuits, National Foods, Tapal Tea and a number of front‑line local companies.

In November, UK-based printing company Taylor Bloxham invested in a Rapida 106 press, which would allow the business to print 18,000 sheets every hour.