O-I Glass (O-I), a glass containers manufacturing company based in the US, will build a new sustainable glass manufacturing facility in Bowling Green, Kentucky, US.

Announced in July 2022, the project was proposed in response to consumer demand for sustainable packaging. It is part of the company’s expansion strategy to boost growth and expand its glass bottle manufacturing capacity.

O-I Glass broke ground for the state-of-the-art glass plant in April 2023. The project is expected to involve an investment of $240m in phases. It will serve the consumer beverages market, mainly the premium spirits category.

The first production line is targeted to commence production in mid-2024. The new facility is expected to provide employment opportunities to 140 people.

Location of O-I’s glass manufacturing plant

O-I Glass’ state-of-the-art glass manufacturing facility will be located in Bowling Green, Kentucky, US.

The facility’s proximity to the Bourbon Trail will enable the company to collaborate with customers, investors and stakeholders. The proximity will also reduce costs and emissions associated with logistics.

O-I Glass manufacturing facility details

The new state-of-the-art facility will feature three manufacturing lines, which will be added in a phased manner.

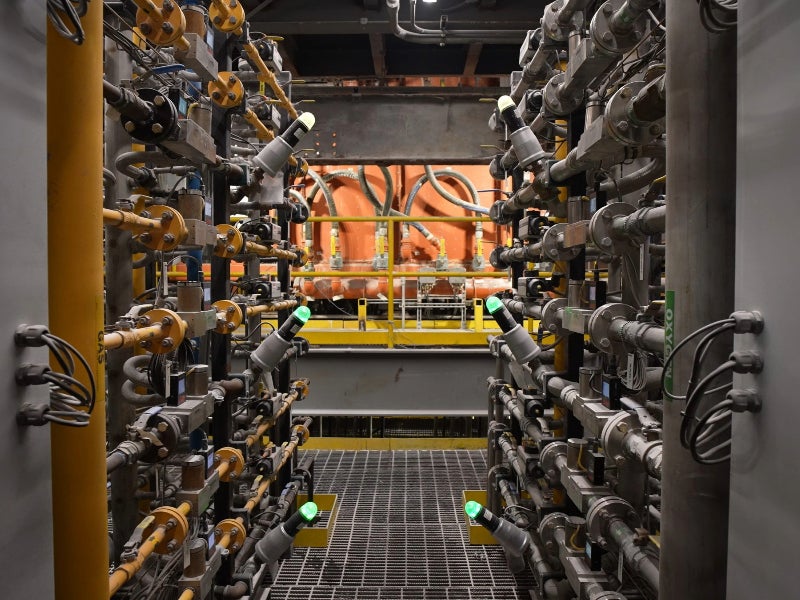

The facility will be equipped with a modular batch system, a melter, and new forming machines. It will be the first purpose-built facility to be equipped with O-I’s glass melting technology, known as Modular Advanced Glass Manufacturing Asset (MAGMA).

The MAGMA technology will support multiple product categories and revolutionise the glass production process by providing flexibility. It will also enable advanced features such as ULTRA light-weighting potential, on-off capability, and control loops to ensure the production of high-quality glass.

The production facility will follow sustainable glass manufacturing practices to reduce its environmental footprint. It will be powered by renewable electricity and gas-oxy fuel.

Tax incentives

O-I received preliminary approval from the Kentucky Economic Development Finance Authority for a ten-year incentive agreement under the Kentucky Business Investment programme in July 2022.

The agreement includes provisions to provide the company with up to $4m in tax incentives. The company is required to meet investment, job creation, and minimum average hourly wage targets to unlock the tax benefits.

O-I is also entitled to up to $1m in tax incentives through the Kentucky Enterprise Initiative Act, which allows it to claim a refund of Kentucky sales and use tax paid for construction and building materials, and equipment used in research and development and electronic processing.

O-I Glass product portfolio

O-I manufactures glass packaging for food, drugs, chemicals, spirits, alcohol, and non-alcoholic beverages. The glass containers are offered in varied sizes and shapes.

The company provides innovative and attractive glass packaging to enhance the brand value of customers and grab customers’ attention.

The internal design of the glass bottle features an embossing, which is invisible when the bottle is full of beverages and can be seen only when the drink gets consumed.

Its Drinktaine product innovation is designed to enhance customer experience while also improving the visibility on the shelf. The glass container has a wide opening that enhances the aroma and retains the freshness and flavour of beverages.

One of the important features of Drinktaine is that it is recyclable and comes in single-serve packaging to allow consumers to drink directly from the container.

Marketing commentary on O-I Glass

Headquartered in Ohio, US, O-I Glass is a prominent partner for numerous global food and beverage brands.

The company is supported by a diverse workforce of more than 24,000 individuals and operates 69 manufacturing plants situated in 19 countries. It partners with customers, suppliers, and associations to make glass recycling solutions available in all the communities where it operates.

O-I implements strategies such as providing community grants, purchasing recycling infrastructure, and encouraging best practices to enhance glass recycling. It contributes to the circular economy by recycling the bottles to produce new bottles with recycled content.

The company aims to increase the recycled content in its glass packaging to 50% on average by 2030. It is also part of Close the Glass Loop, an industry-wide campaign focused on increasing glass recycling in the EU. The campaign aims to increase the glass collection rate in the EU to 90% by 2030.