Standup Pouches, Vials, Trays, and End-of-Line Machinery

PPi Technologies GROUP

The PPi Technologies GROUP is a leading provider of standup pouches, vials, trays, and end-of-line machinery solutions for food, beverage, and personal care market segments.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

The PPi Technologies GROUP is a leading provider of standup pouches, vials, trays, and end-of-line machinery solutions for food, beverage, and personal care market segments.

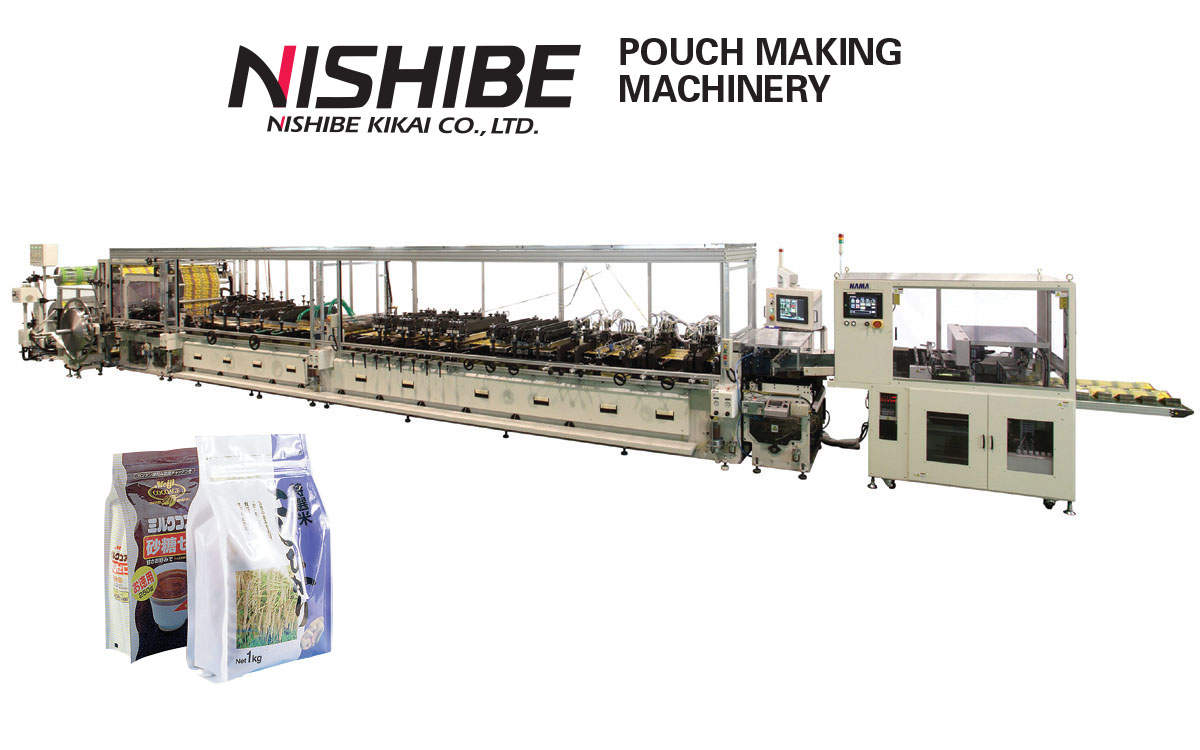

High-speed machines for standup pouches, vials, and trays

PPi Technologies GROUP’s mission is to offer the best global standup pouch, vial and tray solutions available, covering a full range from semi-automatic to high-speed and continuous motion machinery, liquor distribution and contract packing for wellness / environmental products.

Cost-effective, optimised packaging machinery

Investment in machinery and the RoI throughout the entire course of its service-life is very important. PGS Machinery offers service and training contracts to protect the investment through the machine’s lifecycle.

SMART factory and digital production ensures machines communicate with each other and results in optimised production resources. NFC Tagz™ and RFID technologies (patented) will grow in production systems to ensure inventory is available and easily located. Industry 4 is coming, which involves the customer, the product and machinery, and will assist in future internet sales.

The total cost of ownership (TCO) of machinery includes capital to purchase and subsequent machine disposal, utilities to run machines, and material costs, including personnel and maintenance.

PGS Machinery is well-versed in TCO and helps customers understand this during the point of sale.

Optimising efficiency of packaging machines

Our plan is that only one operator will be needed to run several machines. We offer our patented ControlSmart™ system that verifies customer specific control aspects on the machinery and our PLUM™ (Packaging Line Under Management) approach allows 24/7 control over the operator and machines.

Today, many discussions revolve around operating line efficiency (OLE). We look at an eight-hour single-shift operation, no weekends, meaning 2,080 available production hours per annum. We do everything to provide full production for these hours.

If we can maintain full production speed, the customer has an opportunity to produce more products every minute of the year. For example, we often find potential customers who are operating at 60% to 70% OLE, which means they only make profits on this OLE figure losing money on the leftover percentage.

About SECAMP programme

For more than 20 years, our management team has been committed to its Sustainable Environmental Conscious Approach to Machine and Pouch Manufacturing (SECAMP) policy. Our aim has been to stop all landfill, ensuring the correct after-life use of all packaging materials, including incineration and the recovery of energy, metals and slag without harming the atmosphere.

About our social and employee responsibility

As we grow our business, it is our plan to ensure the wellbeing of our employees and the communities we operate in. We have a strong programme of philanthropy and employee education plans that encourage personal growth and development. We have very strong ethical standards and operate fair business practices.

Contact Details

Website

Address

Sarasota

Florida 34234,

United States of America