Oxipack Brings the Future of Leak Detection to Pack Expo Las Vegas 2025

When it comes to food, medicine, or even the pet food we put in our cupboards, the packaging does more than hold the product. It protects what is inside, keeps it safe to consume, and gives us confidence that it will last as long as promised. A single leak can undo all of that by spoiling ingredients, putting consumers at risk, or forcing brands into expensive recalls.

For years, manufacturers tried to guard against this with bubble tests and sniffer tests. They worked, but only to a point. These methods are slow, wasteful, and damaging to the very packages they are supposed to check. They cannot keep up with today’s fast-paced production lines or modern quality expectations.

That is why Pack Expo Las Vegas 2025 is such an important event for Oxipack. As a company, we have reimagined leak detection, offering a cleaner, faster, and non-destructive alternative that reflects where the packaging industry is headed.

Taking place at the Las Vegas Convention Center from 29 September to 1 October 2025, the event will draw more than 30,000 attendees and 2,000 exhibitors from across the packaging ecosystem. At the Healthcare Packaging Pavilion (Booth #N-6048), Oxipack will showcase its latest non-destructive, vacuum-based leak detection systems and demonstrate why the industry is moving beyond outdated tests.

Why traditional tests fall short

Bubble and sniffer tests have been the standard for years, but they come at a cost. They require consumables like water or tracer gas, slow down production, and destroy the sample. More importantly, they often miss micro-leaks that can allow oxygen ingress, accelerating spoilage or microbial growth.

In an era where quality assurance is inseparable from sustainability, these methods are increasingly complex to justify. Destroying packages to prove their integrity runs counter to the industry’s push for waste reduction. And with production lines moving faster than ever, testing methods that cannot keep pace become bottlenecks.

This is the gap Oxipack is closing.

A non-destructive alternative

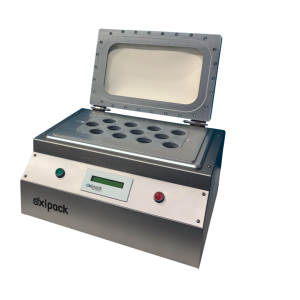

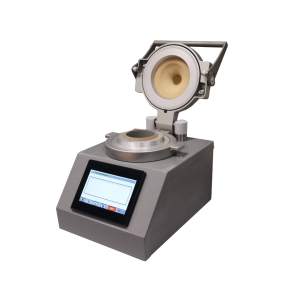

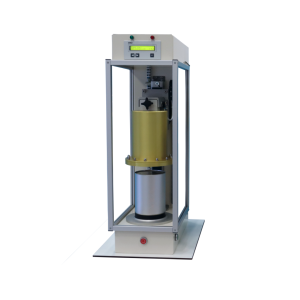

Oxipack’s leak detection systems use a vacuum-based method that identifies leaks by measuring pressure changes. The real strength of Oxipack’s approach is that it checks for leaks without harming the product. Packages stay perfectly intact, which means they can go straight back onto the shelf after testing. For manufacturers, that opens the door to 100% inspection if needed without slowing down production or wasting stock.

The technology also feeds back real-time data that ties directly into automated quality systems. Instead of relying on spot checks or manual inspections, producers can be confident that every single unit on the line is verified. The result is fewer recalls, smoother compliance with international regulations, and real cost savings in materials and workforce.

And the benefits reach across industries. In food, it helps ensure that nutrients are preserved and shelf life stays reliable. In pharmaceuticals, it gives companies the assurance they need for strict container closure integrity testing (CCIT). In pet food, it keeps everything from pouches to tubs fresh, safe, and ready for market.

Built for every kind of pack

One of the things customers notice about Oxipack is how easily the technology fits into various packaging types. Whether it is a tin of pet food, a glass jar of baby food, or a flexible pouch of vitamins, it does not matter. The system adjusts to the format and delivers the same confidence in the seal. Even newer materials, like ultra-light recyclable plastics or unusually shaped bottles, can be tested without fuss. And when a company comes in with something completely new, Oxipack is known for building a tester that works around it.

For production lines that run at speed, the company has also developed in-line systems that test every single unit as it comes off the line. Nothing has to be slowed down or pulled aside. That level of integration is becoming more critical as factories automate, with leak detection now part of the digital backbone of quality control rather than a side process.

Why Pack Expo is the right stage

Pack Expo Las Vegas is where much of the packaging world gathers to see what is next, and that makes it the right place for Oxipack to demonstrate our capabilities for the future of leak detection.

It is also an opportunity for us to meet potential distributors. As Oxipack expands globally, we are looking to build new partnerships and welcome conversations with companies interested in representing our solutions in their markets.

Leak detection has long been seen as a box-ticking exercise in production. But as global supply chains grow more complex and consumer expectations rise, it has become a strategic priority. Companies that can guarantee packaging integrity not only avoid risk but also protect brand reputation and win consumer confidence.

Oxipack’s participation in Pack Expo Las Vegas is a statement that leak detection is entering a new era that is all about being non-destructive, automated, and future-ready. For packaging professionals, destructive tests belong to the past. Non-destructive solutions are here and ready to scale. In Las Vegas this September, the industry will get to see them first-hand.

Meet Oxipack at Pack Expo Las Vegas 2025

- Dates: 29 September – 1 October 2025

- Location: Las Vegas Convention Center

- Booth: Healthcare Packaging Pavilion, #N-6048

- Register: Free registration link with code 27K14