Researchers at McMaster University in Canada have developed a new packaging tray that can indicate the contamination of dangerous pathogens in raw or cooked food packages.

The shallow, boat-shaped prototype packaging tray has been lined with a food-safe reagent.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

It features sloped sides that help direct the food juices to a sensor embedded in a window at the bottom of the tray.

The built-in sensor allows users to detect and indicate the presence of salmonella or other similar dangerous pathogens.

To check this, users need to scan the underside of the tray with their mobile phones.

Utilising this new packaging technology, manufacturers, retailers, and consumers can easily check in real time whether the contents inside a sealed raw or cooked food package have been contaminated by pathogens, without opening the packaging itself.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThis has simplified typically extensive and expensive laboratory-based detection processes.

Furthermore, the process of easily accessing this contamination information will enable public health authorities to quickly trace and isolate contamination while minimising potentially serious infections.

Apart from pathogens, the technology can easily be adapted for testing other commonly found food-borne contaminants, including E. coli and listeria, the involved researchers confirmed.

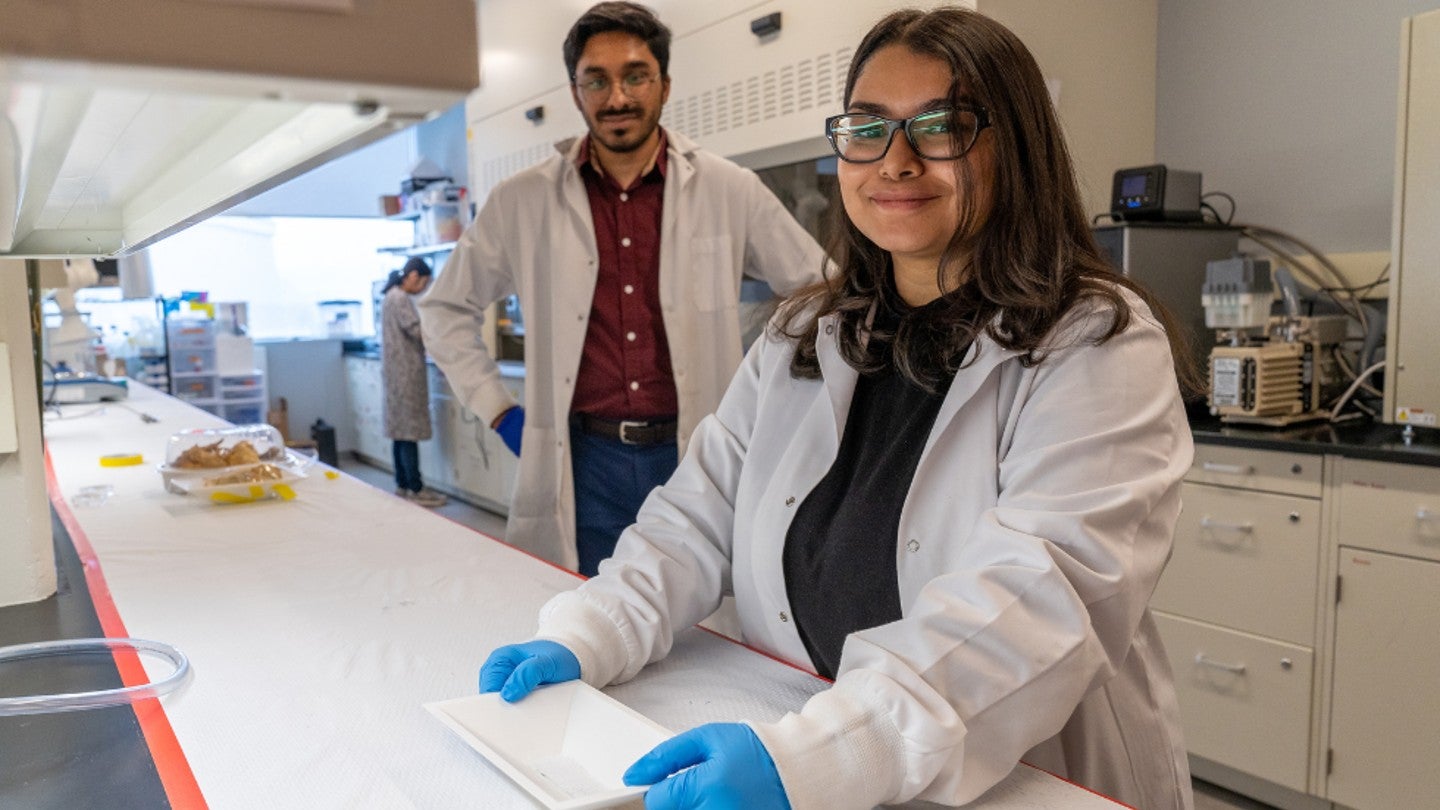

McMaster University researcher Akansha Prasad said: “This is something that can benefit everyone. We are hoping this technology will save lives, money and food waste.”

Prasad is also the co-lead author of the paper, published in the journal Advanced Materials, which details the new invention.

McMaster University researcher and co-lead author Shadman Khan added: “There is a lot at stake with food safety. We wanted to develop a system that was reliable, quick, affordable and easy to use.”

Researchers said that this new technology can potentially significantly reduce food wastage with its accurate identification of food that needs to be recalled and destroyed, rather than broad recalls that result in wasting unspoiled foods.