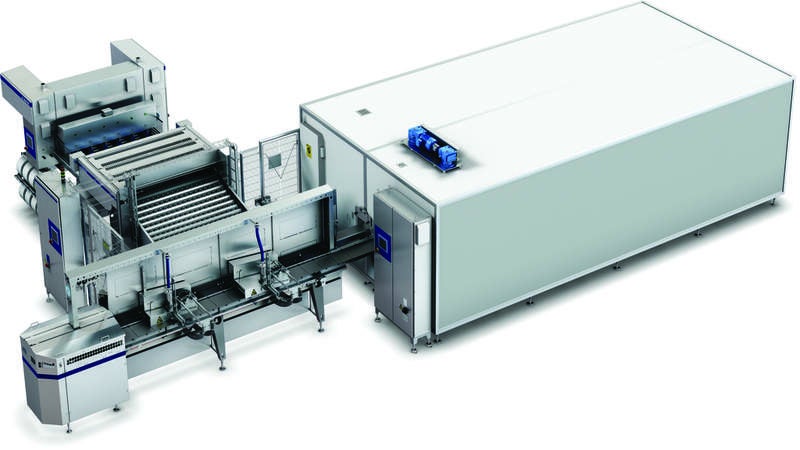

Food packaging and processing solutions provider Tetra Pak has introduced a new ice cream extrusion line that offers better product quality and volume flexibility for medium-capacity producers.

The new line utilises an independently controlled horizontal cutter that slices the ice cream as it comes out from the extruder.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

It ensures a consistent cutting speed and an accurate cut at low production rates.

Tetra Pak product manager Elsebeth Baungaard said: “A surge in competition in the global ice cream market has increased pressure on medium-sized producers.

“They must be more agile in responding to consumer needs, producing greater varieties of products at smaller volumes, while maintaining a high-quality standard and low production costs.”

The new technology also allows the operators to switch to different speeds and movements to produce multiple products on the same line such as sticks, sandwiches, cones, wafer cups, candy bars or cakes.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataIt has a capacity range of 5,000 to 18,000 products an hour, which enables medium-sized manufacturers to accordingly adjust outputs.

Baungaard added: “In addition, customers of the new medium-capacity extrusion line will have access to our Product Development Centre in Denmark.

“Here they can experiment with recipes, seek advice from food technician experts and access training. They will also receive 24/7 technical support to ensure any issues are resolved with minimal downtime.”

Tetra Pak focuses on providing solutions to its customers located across 170 countries.

Image: Medium-capacity extrusion line for ice cream products. Photo: courtesy of Tetra Pak International.