SÜDPACK, a high-performance films manufacturer, is developing a new facility in Erolzheim, Germany, to manufacture its PharmaGuard® recyclable blister packaging for solid-dose pharmaceutical products.

The groundbreaking ceremony for the new facility was held in November 2025, marking the commencement of construction.

Construction is expected to be completed by June 2026, after which production equipment will be installed. Commissioning and start-up activities are scheduled for the third quarter of 2027 (Q3 2027).

Approximately 50 new positions are expected to be created to support operations at the facility. Further expansion phases may create an additional 120 jobs by 2030.

The facility is intended to address the growing demand for PharmaGuard polypropylene-based tablet blisters, as production capacity at the company’s main site in Ochsenhausen is expected to become insufficient over time.

The project also enhances SÜDPACK’s presence in Baden-Württemberg and contributes to the circular economy by providing recyclable alternatives to conventional aluminium/polyethylene terephthalate (PET) laminates.

Location

The new PharmaGuard production facility is being constructed on the site of SÜDPACK’s existing logistics centre in Erolzheim.

The location benefits from the town’s well-developed infrastructure, including direct access to the A7 motorway. This strategic position enables more efficient deliveries to customers.

PharmaGuard production facility details

The SÜDPACK PharmaGuard blister film production facility is designed to include extrusion and packaging processes within ISO 7 cleanrooms. The development will also incorporate a unit dedicated to the regranulation of plastic waste generated during production.

During the initial phase of expansion, an existing hall at SÜDPACK’s logistics centre will be converted to accommodate an ISO 7-certified cleanroom. This will enable Good Manufacturing Practice-compliant production and provide space for a new extrusion line and slitting machine.

The technical infrastructure including the regranulation unit will be housed in a separate building extension.

PharmaGuard blister packaging details

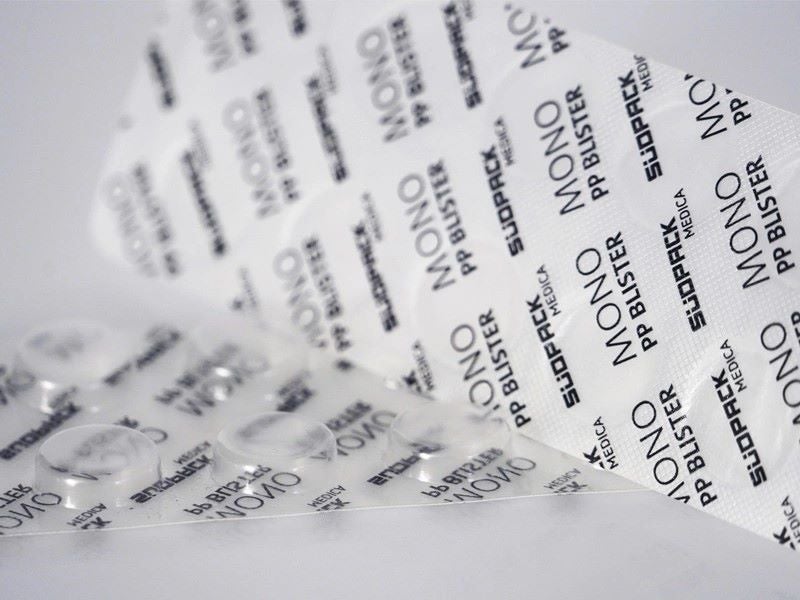

The PharmaGuard blister concept, developed by SÜDPACK Medica, part of the SÜDPACK Group, for solid pharmaceutical applications is based on a polypropylene mono-material.

The packaging concept provides a sustainable alternative to conventional, non-recyclable packaging. It has experienced considerable market demand since it was introduced by the company.

PharmaGuard is recyclable and free from phthalates, vinyl, per and polyfluoroalkyl substances (PFAS) and halogens. It provides reliable protection and enhanced stability, offering versatile barrier performance and robust mechanical strength, with specifications that can be adjusted to suit each packaged product.

Additionally, the packaging offers high transparency, which ensures the product stays visible to the consumer.

An ISO 14040/44-verified life cycle assessment conducted by Sphera has determined that PharmaGuard delivers a notably lower climate impact, measured in CO2 equivalents, compared to aluminium and PET laminates.

The assessment found that 1m2 of PharmaGuard film, comprising a 300 micrometre (µm) bottom film and a 90µm top film, results in 1.54kg of CO2-equivalent emissions throughout the entire value chain, including production, printing, slitting, processing and disposal.

PharmaGuard blister film is suitable for a range of applications including prescription and over-the-counter medicines, nutraceuticals, chewing gum, pastilles and confectionery.

The innovative solution secured various awards such as the German Packaging Award, WorldStar Global Packaging Award, Swiss Packaging Award, and silver at the 35th Packaging Innovation Awards.

SÜDPACK’s existing facility in Erolzheim

The SÜDPACK existing facility in Erolzheim functions as a logistics centre for the storage, packaging and distribution of film solutions.

The company invested €40m ($46.8m) in the construction of the plant. Building work began in 2018, and the facility commenced operations in October 2020, creating around 100 jobs.

The site offers a usable area of 18,800m2 and accommodates approximately 6,700 pallet bays. The ten-hectare plot includes a two-storey production and warehouse building, a four-storey office and staff building, and a high-bay warehouse with a height of 27m.