With various global carbon tax schemes either underway or being deliberated, processing facilities are under increasing pressure to reduce CO2 emissions and fuel consumption. But where should they start? A critical focus area should be on fuel combustion as this accounts for almost 80% of carbon emissions.

Fired heaters are the largest consumers of fuel emitting an estimated 400 to 500 million tons of carbon dioxide (CO2) every year, so even minor improvements in the efficiency of fired heaters can lead to significant savings. To put it into perspective, if any fired heater is 1 or 2% inefficient it can consume an additional $1m in fuel over a year.

Having identified the greatest source of carbon emissions and the piece of equipment which consumes the most fuel, we can now begin to explore mitigation strategies to reduce fuel consumption and CO2 emissions in fired heaters.

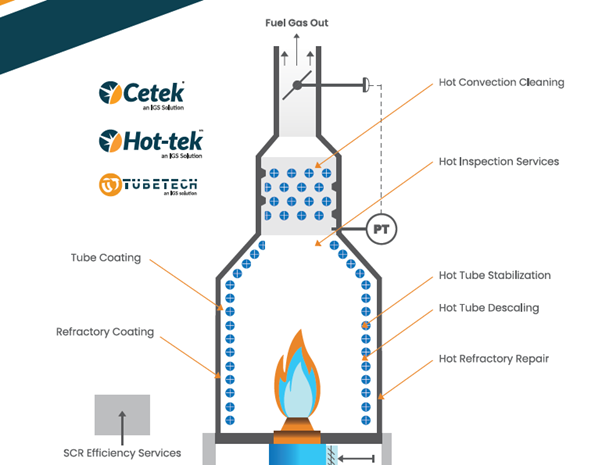

Fig.1 outlines a broader spectrum of CO2 emissions reduction strategies, and this article will focus on process optimisation solutions and more specifically, ways to improve energy efficiency in the radiant and convection sections of fired heaters.

Improving radiant section efficiency

Process fluids are heated in the radiant sections of fired heaters. The fluids travel through steel alloy tubes, which are heated principally by radiant heat generated by burners contained within the refractory lined box. The configuration and condition of the process tubes and the refractory surfaces affect the efficiency of heat transfer in the radiant section.

A common problem affecting radiant section efficiency is the oxidation of radiant tubes.

How does process tube oxidation occur?

Severe scaling due to oxidation on steel alloy tubes is expected in fired heaters due to high operating temperatures. Above approximately 500 °C, the 9Cr-1Mo materials tend to oxidize and may scale very rapidly as temperatures increase. The corrosion rate based on material and temperature is around 0.25mm/year.

What are the effects of process tube oxidation?

To overcome the insulating effect, extra heat is needed and firing rate is increased. This results in increased flue gas temperature (bridgewall temperature (BWT)). Consequently, CO2 and NOx emissions are increased. As the scale grows and further increases in firing rate are required, BWT limitations are encountered, and production rates are threatened.

Carburization

An industry trend to operate fired heaters more efficiently, at lower excess oxygen levels, to save fuel and reduce CO2 emissions has increased the potential for carburization of external surfaces of radiant section tubes.

This leads to grain boundary penetration of carbon, carbide formation, embrittlement of the surface, crack formation and loss of metal. The result is reduced service life of the radiant tubes.

How can carburization and oxidation be mitigated?

Hot-tek online solutions

Online tube descaling is offered by Integrated Global Services’ Hot-tek service. This will immediately improve the radiant section heat transfer efficiency and reduce the bridgewall temperature. This a great short-term fix, however, the improvement is only temporary as oxidation and scale formation will continue.

Cetek ceramic coatings for process tubes

Another IGS service is Cetek high emissivity Ceramic Coatings. This solution provides a durable, protective, thin-film layer on the outer surfaces of process tubes, which prevents oxidation, corrosion, and carburization of the metal and maintains the tube thermal conductivity coefficient close to new tube conditions. The coatings may be applied to existing tubes during a shutdown, or to new tubes at a remote facility where surface preparation, coating and curing of the coating takes place.

What are the expected results?

The average benefit in catalytic reformer heaters is to increase radiant section efficiency by 6.6%, with a corresponding reduction of 6.6% in CO2 emission and approximately 20% reduction in NOx emission.

Refractory surface emissivity: why does it matter?

A significant portion of the radiant energy interacts with the refractory surfaces. The mechanism of this interaction has a considerable effect on the overall efficiency of radiant heat transfer. A major factor in determining radiant efficiency is the emissivity of the refractory surface.

The ultimate radiant heat transfer efficiency is achieved where the enclosure is a black body, where all the surfaces have the maximum emissivity factor of 1.0.

Refractory ceramic coating solutions

Cetek ceramic coatings with emissivity values of above 0.9, has been designed specifically to supplement the radiation characteristics of the refractory surfaces. In use, benefits have been realized of up to 5% in radiant section efficiency improvement, with a corresponding CO2 emission reduction of up to 5% and NOx emission reduction in Ethylene and SMR units of up to 30%.

Convection section efficiency

A common cause for a drop in fired heater performance is fouling build-up on convection sections tubes/fins. Symptoms of convection section fouling include high convection pressure drop due to accumulation of fouling, an increase in flue gas stack temperature, and a decrease in process crossover temperature.

How does fouling occur?

Fouling occurs when deposits accumulate on the tube or fin surfaces. The burner alone is designed to operate with one part per million airborne particulate. This means that a single burner can pass 2.5 tonnes of debris through a heater in a year, some of which will deposit.

Airborne debris is drawn in from the surrounding environment. In a desert location, dust will make up a large proportion of the waste. If surrounded by agriculture, waste from harvesting will accumulate, and in an industrial location, waste products from surrounding plants will also make up the debris being pulled into the fired heater.

What are the effects of fouling?

Excessive convection section fouling can result in:

- High fuel consumption and decreased heater efficiency

- Running the burners out of oxygen

- Unburned gas accumulates in the firebox

- Increase in flue gas temperature which can warp tubes and lead to failures

- A reduction in heater throughput

- Exceeding stack temperature limit

All these effects negatively impact plant performance, but perhaps the most significant effect of fouling is an increase in CO2 emissions. If fouling is left to worsen and emissions become excessive, refineries may be liable to pay government fines.

How can fertilizer plants mitigate fouling and restore efficiency?

What are the pros and cons of traditional cleaning methods?

There are two commonly used offline cleaning methods to tackle the issue of fouling: chemical and dry-ice blasting.

Chemical cleaning

Chemicals can be used when an asset is online, however, if the nature of the fouling is unknown, it is difficult to predict how it will react with certain chemicals. Therefore, chemicals can compound the issue of fouling, creating hotspots in areas that the chemical has not managed to penetrate or even reach at all.

During a shutdown, the refractory lining of the convection section can become saturated with water-borne chemicals which may result in changed high-temperature properties of the refractory, leading to premature failure.

Dry-ice blasting

Dry-ice blasting can be undertaken during the operation of the unit and is offered by IGS/Hot-tek services. It provides a limited benefit, since accessibility reduces the ability to reach more than 40% of the tube surface area, but often this is sufficient to provide a significant improvement until a planned shutdown.

What is the most effective method to restore heat transfer?

A comprehensive solution is offered by Tube Tech, an IGS Solution, which uses robotic technologies to remove more than 90% of convection section tube fouling during planned turnarounds.

Tube Tech has developed this system in-house and is used by major fertilizer plants and other facilities around the world. On average, clients report a 3-5% increase in thermal efficiency and up to 15% reduction in CO2 emissions.

The robotic system is designed to access the most difficult-to-reach convection banks. It is remotely controlled by a technician, ensuring safety standards are met, and the engineered lance penetrates deep between each tube row to remove any type or level of fouling.

Case study: rover restores stack temperatures in holland

The challenge

A fertiliser production plant in Holland was suffering from heavy fouling of the convection section of its Primary Reformer Furnace. The outlet stack temperature was running at 170oC, 30 degrees above the design stack temperature figures, due to the level of fouling present.

The asset had never been cleaned before, so the client contacted Tube Tech to resolve the issue after previous impressive cleaning results on other assets at the plant.

The solution

Four teams of cleaning specialists were mobilised. Two teams worked during the day and two at night to complete the job within 48 hours. To remove the build-up of fouling and restore the stack temperatures to design efficiency, the teams used a robotic cleaning system; a semi-autonomous rover and lance that is pre-programmed with the dimensional data of the asset and can access more than 95% of the surface area to be cleaned.

The patented system is the only technology able to penetrate deep between each tube row and guarantee to remove more than 90% of fouling. Deposits were successfully removed from the tube surfaces, within the allocated time and within budget.

The benefit

The level of fouling present was the result of years’ of debris build-up which had a negative impact on the stack temperature and the ultimate productivity of the asset. Left uncleaned, the fouling would have cost the plant millions of euros in lost revenue over the course of a year.

The fired heater stack temperatures were restored to design parameters and CO2 emissions were also reduced by more than 3%.

Conclusion

Fired heaters are a critical piece of equipment for fertilizer production plants around the world. With rising fuel costs and stringent emissions legislation, it is becoming increasingly important to ensure that mission critical assets, particularly fired heaters, are performing efficiently and at full capacity.

Maintaining these assets regularly and thoroughly will maintain output, increase asset life, reduce the likelihood of unplanned outages, reduce stack temperatures and emissions, and deliver a significant ROI.

To speak to a fired heater performance expert, or to learn more about IGS solutions, download the free whitepaper here.