As modern consumers become increasingly aware of industry’s impact on the planet, food manufacturers are rightfully facing increased pressure to reduce the emissions and waste created by its machines and production processes. Now, more than ever it is an industry imperative – dictated ultimately by consumers.

Setting ambitious sustainability goals is a fundamental part of the strategy for an organisation such as GEA Group when developing new food processing equipment, says Bart Leenders, Product Owner Preparation, GEA Group. “Food processing equipment relies on CO2 or nitrogen. A lot of energy is required to produce those gases, which must be distributed in pressurized vessels at the production sites. So, if you can reduce that, it can have a positive impact on the environmental footprint,” he says.

While reducing emissions and carbon footprints is extremely laudable and significant steps have been taken across the industry, some manufacturers have struggled to introduce that thinking while maintaining product quality in automated food processing technology.

Producing large quantities of a popular food staple such as chicken nuggets with consistent results, meeting stringent product specifications each time, requires full control of the process. What’s more, it has to be done while creating fewer emissions and waste on the production line. A key to that, in this initial stage of the whole process, is maintaining control of the viscosity of the meat mixture throughout the process and keeping the temperature consistent and safe.

This is where the groundbreaking GEA Batch2Flow comes in. Historically, the creation of uniform, perfect nuggets has always required specialised, chilled cold rooms to store the meat between the mixing and forming stages of the production process. It also relied on hands-on, labour-intensive human intervention; Batch2Flow can eliminate the hygienic risks associated with manual operations, as well as reducing energy usage at the same time.

Creating perfect conditions to safeguard quality of mix

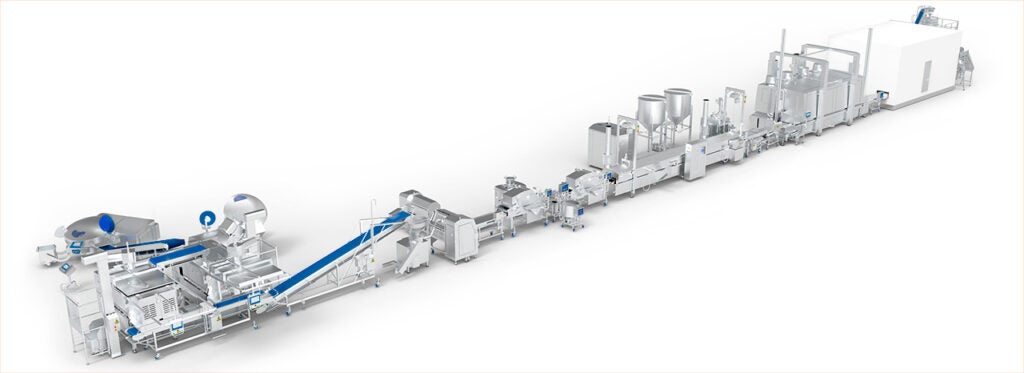

The preparation aspect for a food such as nuggets has always been a batch process, while further processing, starting from forming is in-line, automated. Now, with Batch2Flow that preparation is connected with further processing in a smart way in a full in-line process. That increases product quality, reduces labour and risk of human error, optimises process control and ultimately reduces the carbon footprint – making it something of a missing link between those mixing and forming processes. The solution is therefore pushing the dial forwards for high-capacity, high-quality, demanding applications for meat-replacement and poultry applications and for global food manufacturers, innovative food processors and for medium to high-capacity producers.

Prior to its introduction, most customers used standard, 200L trollies to move their dough mix from the mixer to the former machine. Transporting, storing, and loading trolleys is arduous and time-consuming, and therefore temperature and viscosity of the product changes from the previously optimum level first achieved in the mixer.

Conversely, Batch2Flow’s innovation allows the mix to be consistently and safely maintained within the mixer until it is required. Consequently, it is at the precisely required temperature and viscosity by the time it arrives at the former.

“Previously it was not possible to handle this kind of cooled, stiff and sticky mixture on belt conveyors. The Batch2Flow technology includes a combination of mechanical, software and process solutions that enable that this kind of product can be handled on a belt conveyor system,” says Jakob Veber, Product Expert, Food Solutions.

“This has the advantage that you can eliminate operator costs for the loading and manual shuffling of trolleys between mixer and former. You also avoid the risk of mixing up different batches. No cold store is needed for buffering the trolleys because in the Batch2Flow process you buffer the material in the mixers and then automatically discharged when needed. This increases the efficiency and process control of the full line.”

Also, says Veber, manufacturers avoid subjecting their carefully cooled product to multiple surfaces with ambient temperatures that will immediately start deteriorating their mix properties – when the temperature goes up, viscosity goes down, meaning you have less control of your downstream forming and thermal processes. With Batch2Flow, you can optimize the target parameters throughout the production line.”

Customer feedback

With less cold room space required to be maintained, cleaned, and powered emissions, water, cleaning chemicals and waste are reduced. Add in the guarantee of a consistent product, plus additional benefits for food safety, and the benefits of Batch2Flow to GEA’s customers are manifold. And there are significant cost-savings to be had by investing in its technology too. “All the advantages of Batch2Flow are valuable to our customers,” says Veber.

“The direct savings on operator costs appeal a lot – not only due to the wages saved for operators on the day, evening and, perhaps, night shifts – but also because it is a huge challenge in many places to find workers who are willing to take this kind of work these days. Batch2Flow’s automation makes it such a game changer.”

For Veber, “the fact that you cool only exactly to the required temperature and viscosity with minimum consumption of expensive CO2 or N2 and can adjust the settings of your forming machine and thermal equipment downstream. It can also potentially lead to significant savings and process benefits such as less give-away and more consistency at forming, less doubles at coating, no over-cooking and more yield during cooking, more optimal loading during frying and less energy used in freezing. A consistent product throughput gives the opportunity to heat and cool more efficiently and therefore save on energy by less consumption of cooling gas and less give away from your forming process.” That means, he says, “a homogenous product, day in and day out, is also a quality parameter.” The short-term gain of using Batch2Flow is fast, says Leenders. “The return of investment is really short. People see it immediately.”

Batch2Flow’s solution for automation in preparation has seen it win the Gulfood Manufacturing 2022 Award for Innovations in Food Processing. A system that saves money, utilities, space, labour, and its impact on the environment – all while producing outstanding consistency of product may seem too good to be true, but the far-reaching benefits for plant managers all the way down the chain to consumers are clear to see with this clearer, cleaner and more-cost effective option.