Danish manufacturer Brodrene Hartmann expanded its packaging operations into the US Midwest, by building its first egg packaging production facility in Rolla, Missouri. The company operates under the name Hartmann US in the American market.

The investment for the project was in line with the company’s ‘Unpacking Our Potential’ strategy, which focused on achieving growth and efficiency by 2017.

The expansion provided additional production capacity to the company and increased its distribution efficiencies.

The existing egg carton plant became operational in early 2017, while the company started hiring in mid-2016 and created 50 new jobs.

Brodrene Hartmann closely worked with state and local authorities, which supported the investment with a number of tax benefits. The Rolla Regional Economic Commission (RREC) played a key role in attracting the investment to the region.

Background of Missouri egg carton facility

Brodrene Hartmann served the North American market with its Brantford production facility in Ontario, Canada. The facility witnessed increased capacity utilisation in the recent years, which contributed significantly to the company’s growth and profitability.

To continue the positive development, the company planned to expand its operations into the US market with the new facility. With presence in both Canada and the US, the company aims to gain a major market share and lay a strong foundation for business expansion.

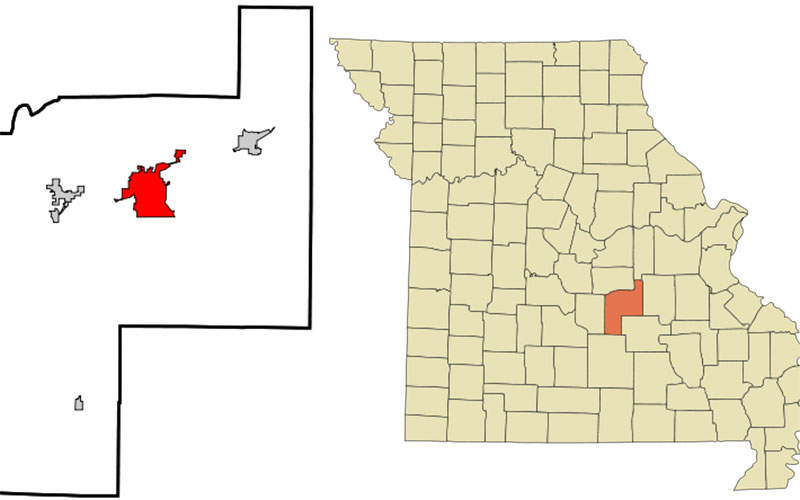

Location of Brodrene Hartmann’s Midwest egg carton production site

The State of Missouri, the Missouri Partnership, and the City of Rolla assisted Brodrene Hartmann in choosing a strategic location for its first investment in the US. The plant is located in Hy-Point Industrial Park, which is one of the three industrial sites in Rolla, Missouri.

Missouri was chosen out of the five competing Midwest states due to its strengths in advanced manufacturing, competitive business environment and the availability of regional manufacturing workforce.

The location also provides better transportation access to customers across the country from the I-44 corridor and the intermodal rail connections in St Louis and Kansas City.

Production details of Hartmann’s Rolla packaging plant

The packaging plant is located in an existing 334,000ft² facility, which was retrofitted to produce the company’s egg cartons. It manufactures moulded-fibre egg cartons from recycled newspaper sourced from the Midwest and distributed nationally.

The egg cartons are made from eco-friendly raw material and complement the eggs as natural products.

Investment and financing details

The carton-producer invested $30m in the Rolla facility and plans to double the investment in the next six years. The investment will contribute to the company’s long-term financial goals of increasing its revenue.

The strategic economic incentive packages offered by the Missouri Department of Economic Development, Phelps County, the City of Rolla and Rolla Municipal Utilities will be released based on the job creation and power usage criteria.

Sustainability of moulded-fibre packaging

All the products produced by Hartmann are based on recycled paper, which is a renewable, CO2-neutral and biodegradable resource.

The moulded-fibre packaging made of recycled newspaper represents a highly efficient use of a renewable resource that would otherwise be disposed. The packaging can be reused, recycled and composted, all of which are sustainable ways of disposal.

Egg trays made of moulded-fibre can be reused for five to ten times before returning them to fibre production. The combination of reuse and reprocessing, known as double-loop, is not common, even among paper products.