Vetropack Group, a glass manufacturing company based in Switzerland, opened a new glassworks facility in Boffalora sopra Ticino, Italy, through its subsidiary Vetropack Italia.

Announced in November 2018, the new facility was built with an investment of more than SFr400m ($418.8m). The ground-breaking ceremony for the facility’s construction was held in October 2021 and the plant operations commenced in October 2023.

Boffalora sopra Ticino is the sole Vetropack location in Italy. It replaced Vetropack’s existing facility in Trezzano sul Naviglio to predominantly serve the Italian market.

The employees at the Trezzano sul Naviglio plant were transferred to the new facility.

Location of Vetropack’s glassworks facility

The new production plant is located in the industrial site of Boffalora sopra Ticino, near Milan, on the former Reno di Medici paper mill site. The site is located at a strategic junction that connects to the road network.

The existing SP225 road system has been modified to improve accessibility and safety. Public car parking and a lorry park are constructed to avoid disruption in the existing roadway.

The site also provides sufficient space for future expansion.

Vetropack’s Boffalora facility details

The new facility spans 347,000m² (3.73 million square feet), of which 170,000m² (1.82 million square feet) is used for production facilities, including the batch house, Hot End building and Cold End building.

The facility is equipped with high-performance, advanced technologies to increase flexibility and resource efficiency. It also features closed-loop systems to reuse water and exhaust heat from furnaces while filter systems reduce emissions.

The plant also enables more flexible production, accommodating smaller batches and allowing Vetropack to quickly react to dynamic market conditions.

The existing moulds from the Trezzano sul Naviglio plant were reused at the new plant.

Construction details

Site-yard set-up, land reclamation activities and the beginning of the Hot End building foundations were developed between September and November 2021.

Between November 2021 and January 2022, the Hot End building foundations were completed, and a section of the sewage system was put in place. Excavation works for the Cold End building plinths and foundation work for one furnace, Furnace 95, were also undertaken in this period.

Construction of the Hot End building continued between February and March 2022, along with the start of construction of the Cold End building and base camp.

Installation of batch house cullet silos and construction of the energy recovery building commenced between May and June 2022. During this period, the Hot End building’s roof structure installation was started, and the chimney stack of the glass cleaning plant was completed. In addition, the excavation work for the foundations of the administration building and the installation of the Cold End building’s precast walls and roofs commenced.

Vetropack commenced work on the firefighting reservoir between July and September 2022. Construction on the batch house’s cullet storage and raw material silos was also begun, along with the construction and insulation of the Hot End building’s facades and roof.

Other works undertaken during the period included the installation of the furnace pillars in the Hot End building control room, the administrative building’s prefabricated concrete frame, and the warehouse foundations.

The Boffalora plant has been operational since May 2023 for the initial heat-up of the two melting furnaces.

Sustainability features

Vetropack incorporated various sustainable measures to reduce the environmental footprint of the project. The facility is being built by reusing secondary materials, such as the demolition material from the former paper mill. The design is also expected to have the lowest levels of day and night noise emissions within legal limits.

Recirculation systems are installed to reuse the water used for production and exhaust heat from the blast furnaces. Emissions are significantly reduced with the help of the latest filter systems.

The facility is installed with photovoltaic systems to generate renewable energy. In addition, 31,000m² (333,681ft²) of green cover is created on the site, which is accessible through a 2.5km cycle and pedestrian path.

Contractors involved

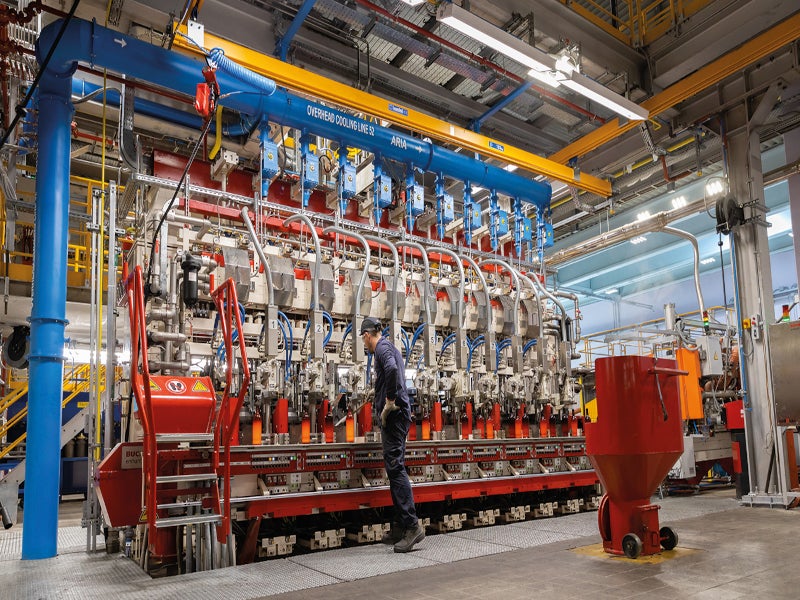

Bucher Emhart Glass (BEG), a provider of glass container manufacturing technologies, constructed eight pneumatic IS glass container forming machines at the new facility.

Vetropack’s new facility was designed by A2N Studio Associato, an architecture company based in Italy.

Construction company GSE Italia was appointed as the general contractor for the project.

STI Engineering, a provider of design and consulting services, was subcontracted by GSE for mechanical, electrical and plumbing (MEP), detailed structural design, and site supervision.

GSE also subcontracted Montana, an engineering consultancy, as the environmental consultant.

ARTELIA Italia, an engineering, project management and consulting company, provided project engineering and building information management (BIM) services.

The batch house and two cullet return systems for the project were supplied by Zippe, a developer of batch and cullet systems for glass plants.

Steel Structures designer and developer BIT was contracted to supply the hot and cold metal framework for the plant.

Revimac, a glass container equipment supplier, supplied and commissioned various equipment, including loaders, conveyors, piping systems, cable trays and cables.

Ventilation technology company Aerotec was awarded the contract to supply a natural ventilation system.

Fire risk assessment services provider Rainieri Studio Tecnico was the firefighting consultant for the project, and i.Geo, a provider of geophysical and geological consulting services, was the geological consultant.

Germany-based independent consultant CM.Project.ing is also involved in the project.

Marketing commentary on Vetropack

The Vetropack Group is an independent, family-owned company with headquarters in Switzerland. It is a supplier of high-quality glass packaging for the food and beverage industry. It also provides tailored solutions for the specific needs of its customers.

Vetropack employs approximately 4,000 people and operates eight glasswork plants in Switzerland, Austria, the Czech Republic, Slovakia, Croatia, Ukraine and Italy. Vetropack Italia produces, sells and distributes glass packaging in Italy, as well as select export markets.