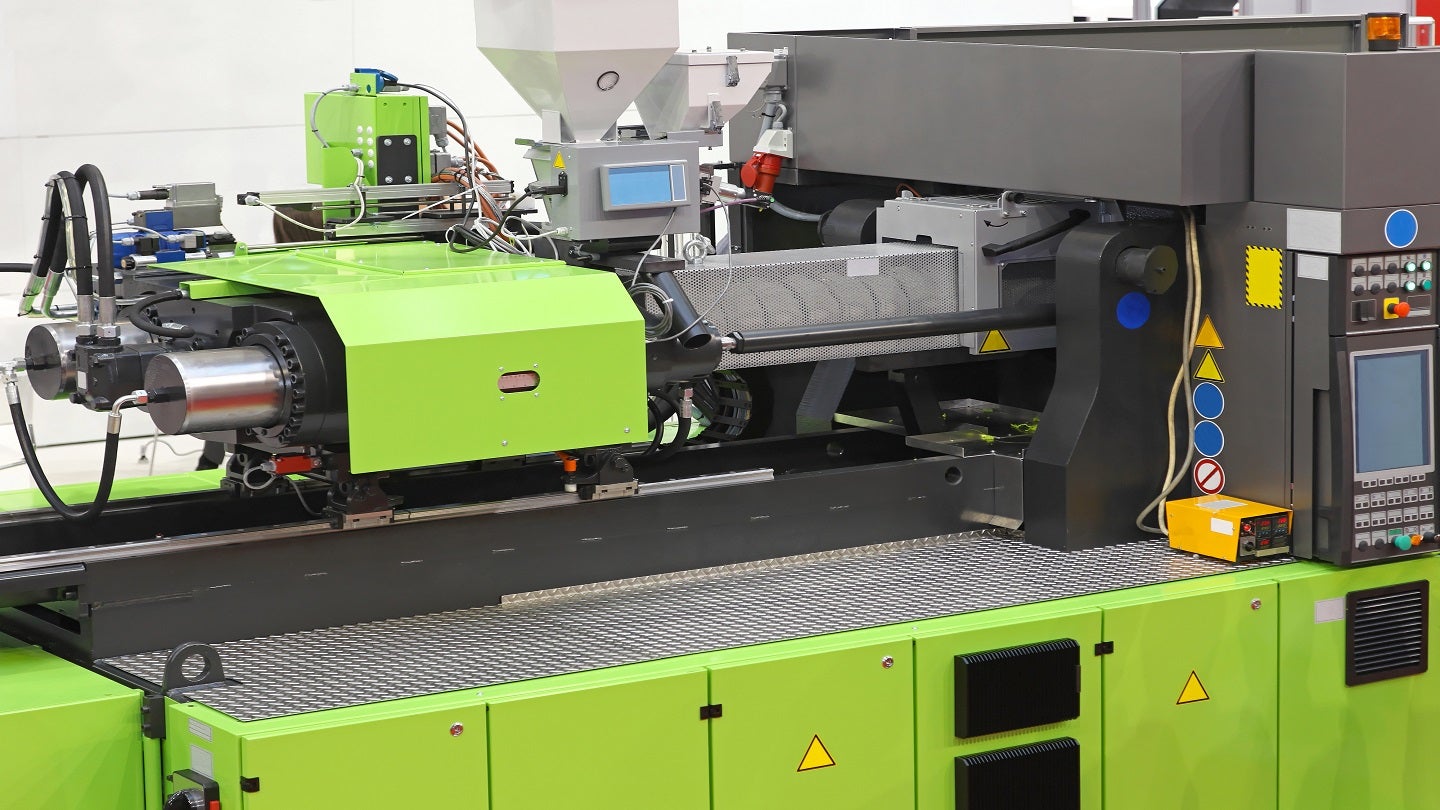

Temperature-controlled packaging manufacturer Pelican Products has invested in a new injection moulder machine at its US-based factory.

Dubbed Thor, the new machine is claimed to be one of the largest in the Western US region.

The machine is equipped with 3,000 tons (t) of clamp pressure that can produce a new Pelican case every 209 seconds.

In addition, Thor features six chambers, each of which can accommodate coloured materials.

According to Pelican, this will improve efficiency and streamline changes during its manufacturing process and will also enable the company to meet evolving market demands.

Thor is set to expedite Pelican’s production capabilities by creating larger cases at a faster pace, without compromising on its quality and durability standards.

The machine manufactures products and models of cases, including the 1755 Air Case, as well as the V730, V770, and V800 Vault Cases.

According to Pelican, the installation of Thor required the deployment of a custom crane and new infrastructure.

The new machine has now dethroned the company’s largest machine out of its 23 on the factory floor, moving the 1,800t Colossus to second place.

Pelican COO Kevin Miniard said: “Pelican is a global leader in protective cases – our products are sold around the world. Still, we work hard to keep the majority of our production and our workforce here in the US. The investment in Thor demonstrates that commitment – as well as our nonstop drive toward innovative solutions.”

Pelican operates a network of 23 international sales offices and 11 manufacturing facilities in 27 countries.