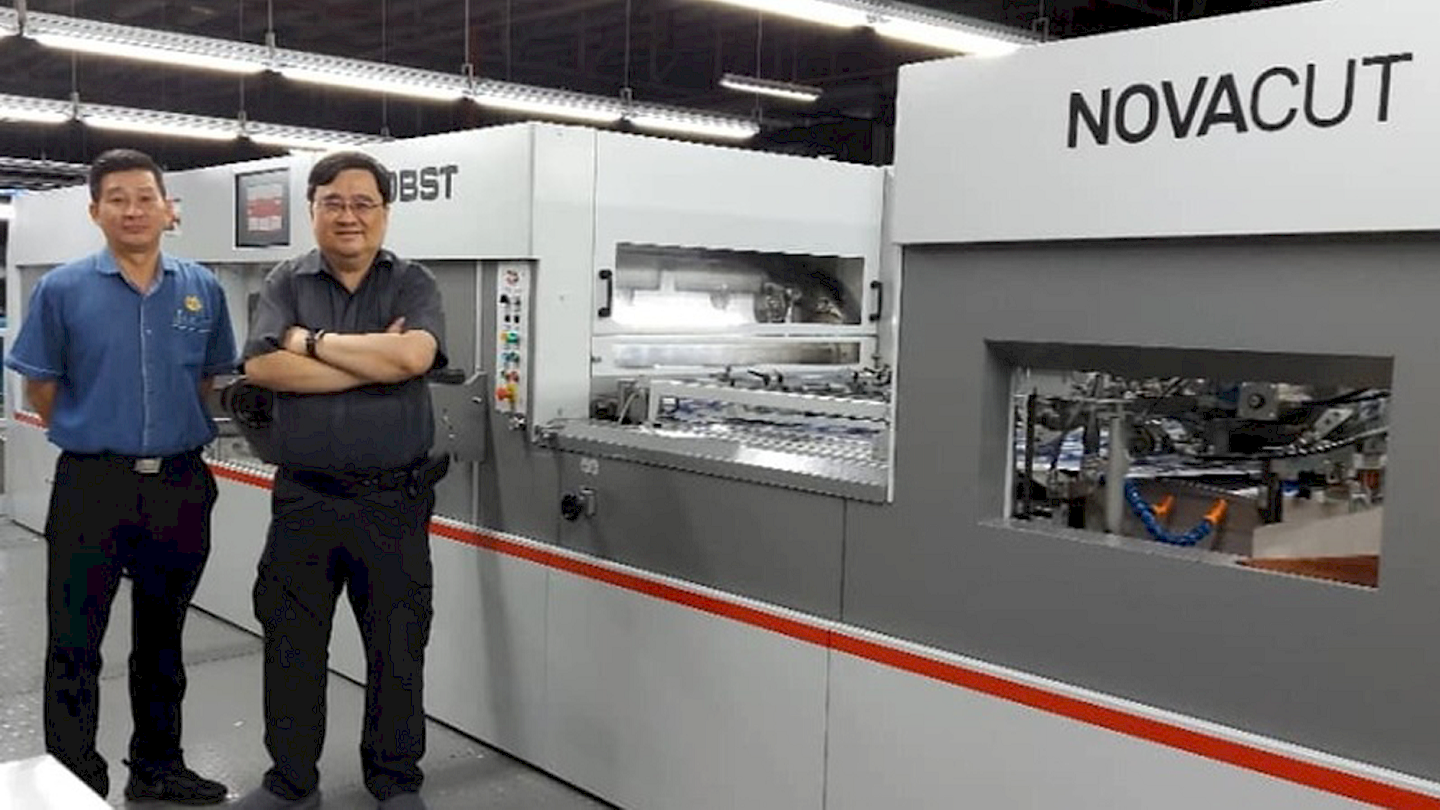

The Phoenix Press, a manufacturer in the Malaysia and Asia Pacific region, has invested in BOBST’s NOVACUT 106 ER die-cutter.

The new machine handles paper, cartons, solid boards, and light corrugated boards up to a maximum size of 1,060mm x 760mm.

With a processing speed of up to 7,000 sheets per hour, the new solution is intended to increase Phoenix’s capacity, improve productivity, and speed up delivery.

In addition to its improved production cycles, NOVACUT 106 ER comes with automated setup and changeover features, which reduce bottlenecks and enhance overall efficiency.

The advanced die-cutting capabilities of the machine also reduce materials and energy consumed in the process.

The investment will enable Phoenix to serve a wider range of customer requirements and their growing demand.

Phoenix production manager YL Ooi said: “The NOVACUT aligns with our requirements perfectly and its integration into our factory floor has already increased productivity and efficiency.

“Moreover, the machine boasts a very user-friendly interface, featuring an intuitive HMI and straightforward, systematic instructions catering to all skill levels and making it very popular with our operators.

“Our customers have noticed a significant improvement in turnaround times. They appreciate our ability to fulfil their orders promptly, which will no doubt lead to increased loyalty and more repeat business.”

The latest investment strengthens more than 20 years of partnership between Phoenix and BOBST.

The NOVACUT 106 ER Autoplaten flatbed die-cutter will complement two older die-cutters and two folder-gluers, also provided by BOBST.

Phoenix operates a 16,000m² modern printing plant in Prai, manufacturing an extensive range of carton packaging products.