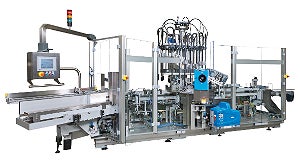

Optima presents turnkey equipment for natural liquid additives used in the beverage industry. Utilising a special process, the round and square containers are sterilised inline before being filled via mass flow metering.

The two-stage capping process achieves precise and consistent torque. At the end of the line, the aluminum seal in the cap is sealed to the bottle mouth by induction. In addition, the laminar flow over the filling and capping area ensures that hygienic conditions are maintained.

The downstream checkweigher monitors the filling process and ensures that products leaving the line adhere to packing regulations and label claims. Labels are printed inline and applied to both sides of the bottles. At the push of a button, a clean-in-place (CIP) function automatically takes over the cleaning of the liquid product path. The Optima equipment covers a wide range of formats from 50mL to 1000mL at an output of up to 50 units/min, and requires only a few size parts.

Ergonomic access to the machine allows for quick format changes. Production data is transmitted to a higher level factory control and data acquisition system. The owner of the machine, Erbslöh AG, will be present at different intervals during the fair, while Optima personnel will be available to answer any questions.

A second exhibit at the Optima booth is a CMF cartoner. The modular construction offers optimal flexibility, and the exceptionally gentle operation ensures a high quality process with minimal rejects.

Especially in the cosmetic industry, the frequency of format changes means that machines need to be set up in the shortest possible time. The CMF is tuned to this, being able to perform automatic or semi-automatic format changes. The model on display includes an embossing station as well as a pick-and-place for placing the products into the cartons at a rate of up to 200 pieces a minute. Additional modules, such as a booklet dispenser, labeller and other functions, can also be incorporated on the machine.

Optima Consumer, with its broadly expanded product range, offers concentrated know-how for liquid and dry products. Tailored machine solutions, including turn-key lines, are available for nearly every application.

Optima, at FachPack 2012, will appear at: Hall 2, Booth-Nr. 2-213, September 25-27, Nuremberg, Germany.