How our Collaboration with Jorgensen Simplified Leak Detection Integration

Some projects just click. From the very first conversation with the team at Jorgensen, it was clear we were working with people who shared our values: precision, practicality, and a commitment to making production lines work smarter.

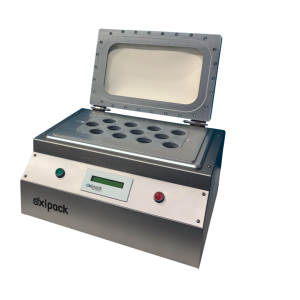

Jorgensen Engineering is known for building sophisticated, high-speed canning systems for the food and infant formula industries. As a machine integrator, they design and assemble full production lines, combining their own machines with best-in-class components from other providers. While Jorgensen has been manufacturing leak testers for nearly 20 years, they reached out when a mutual customer specifically requested Oxipack technology for a new project.

What followed was a model collaboration. They built the machine. We delivered the leak detection unit. It fits seamlessly.

“So nice to receive a complete plug-and-play unit where somebody considered the last bit. Thank you,” was the response we received after delivery. For us, it was validation of a simple principle: when we customise thoughtfully and deliver precisely, we make our partners’ jobs easier, and their systems stronger.

Designed together, integrated both ways

Our role was to supply a standalone leak detection chamber and control cabinet that could be integrated into their existing machine design. But this was not a one-way fit. Thanks to close collaboration between both of our 3D engineering teams, we were able to anticipate every technical detail. And we did not stop there. We even implemented extra features on our equipment to better support their specific product handling requirements.

The result? A painless, plug-and-play integration.

Their team did not need to modify or adapt anything. One of their project leads wrote, “I have not worked on many projects with such easy cooperation.”

That kind of feedback is what we aim for. It means we did more than deliver equipment. We delivered confidence.

Why it worked

Three things made this partnership successful:

- Mutual trust and clarity. They knew exactly what they wanted. We focused only on what we do best: leak detection.

- Designing for the integrator. We customised our standard technology to fit Jorgensen’s space and specs, so they did not have to adjust their process.

- Shared standards. Both teams were aligned on quality, efficiency, and getting it right the first time.

In total, the project took just 16 weeks from start to factory acceptance. That is a short timeline for anything involving line integration, and a testament to how smoothly things went.

A different kind of collaboration

This was not our usual type of project. Normally, we supply full standalone systems. But in this case, we simply delivered the leak detection hardware and handed over full integration control to Jorgensen. They made it work brilliantly.

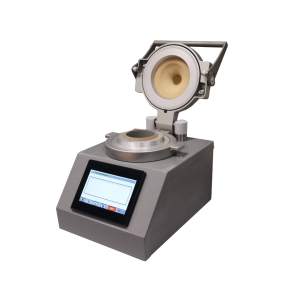

“Previously, their machines were set up to work with gas tracing systems such as helium or CO₂ detection, methods that are well-established and effective in many applications. However, for this specific project, they saw clear advantages in adopting vacuum decay technology. It offers a simplified setup with fewer consumables and less maintenance, while still meeting this customer’s standards for reliability and performance.”

An open invitation to machine builders

For us, this project confirmed something we have believed for a while: we do not need to build the whole machine to bring value. If you are a machine builder working on packaging systems, we would love to talk. We can help you integrate vacuum-based leak detection into your design, quickly, reliably, and without disrupting your core machinery.

Our goal is to be the easiest partner you have ever worked with. If you are already designing the line, why not make it leak-proof too?