Growth, Groundwork, and What Comes Next for Oxipack in 2026

For Oxipack, 2025 has been a year spent tightening processes, learning from field cases, and building a stronger foundation for what we want to deliver next.

Across packaging, the challenges are still the same. Manufacturers are expected to protect product quality, meet throughput targets, reduce waste, and stay audit-ready, often while materials and formats continue to evolve. Leak detection sits right in the middle of that. If the seal fails, everything downstream becomes harder.

A year shaped by R&D

We have had a busy year of development work, not just in terms of ideas, but in turning ideas into testable, buildable solutions.

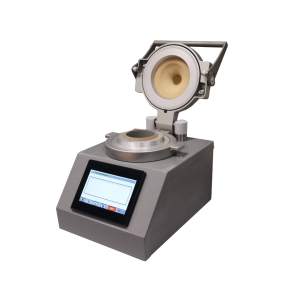

A significant milestone has been our step into the pharmaceutical market. It is not enough to bring an existing approach into pharma and hope it fits. Regulated environments demand a different level of procedure, documentation, and confidence in both the method and the workflow around it. We have been building toward that reality, and in 2026, we are committing even more focus to it. We have assigned dedicated business development capacity to the pharma sector, so that the people leading those conversations can delve deeply, speak the language of the industry, and support customers with the seriousness the sector expects and deserves.

Alongside that, we have continued working on a pipeline of research and development (R&D) projects that reflect what customers are asking for right now:

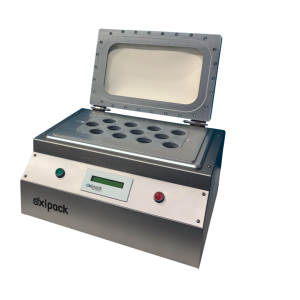

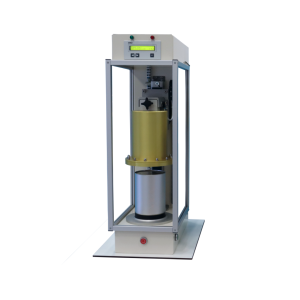

- An improved, highly sensitive bottle leak tester, aimed at customers who need higher sensitivity and more confidence around tiny integrity failures.

- A vacuum meat and cheese leak detection solution, designed for the practical challenges that come with vacuum-packed products.

- A new semi-inline machine that sits next to the production line and tests a fraction of each batch, which we are preparing to showcase at Interpack in May 2026. For many manufacturers, a complete inline solution can feel like a step that is either too expensive, too complex, or simply unnecessary for their risk profile. Semi-inline is the in-between option. It is more automated than stand-alone testing, but without the footprint and integration burden of a complete inline system.

- Standardised CCIT, supported by continued development work and deeper learning from real-world pharmaceutical requirements.

- Even more collaboration with universities and research partners, because some of the best progress happens when you validate ideas with rigorous external thinking.

Making service and support feel like part of the product

One of the clearest lessons in industrial technology is that buying a machine is only the beginning. A customer’s real experience is shaped by what happens after commissioning. For example, how quickly they get confident, how well the knowledge transfers between shifts, and how easily the system becomes ‘normal’ on the line.

That is why we have been reworking how we present and deliver Oxipack Care+. We have been reviewing the platform, researching where we can improve, and planning updates to roll out in 2026. Training materials and supporting information are a big part of that. Some of this work is still happening behind the scenes, but the intention is to make it easier for customers to get value faster, and for teams to stay capable even when people change roles.

In the same spirit, we have also started a customer success programme that follows up with customers after a machine has been delivered. The goal is to learn what is working in the real world, spot friction early, and support customers before minor issues become unnecessary downtime.

Integration is becoming the competitive battleground

Of course, leak detection does not live in isolation. It has to fit into lines, OEM environments, and broader automation strategies. As such, we have been expanding cooperation with large suppliers and working on OEM projects that bring leak detection closer to where manufacturers actually need it.

Earlier this year, Oxipack completed an integration project with Jorgensen, demonstrating how non-destructive leak detection can be cleanly embedded into existing equipment without complicating operations or validation. Similar OEM projects are now taking shape with larger packaging machine suppliers, reinforcing a shift toward leak testing that fits seamlessly into modern production environments rather than sitting on the sidelines.

Trade shows are still where the market pressure becomes visible

There is a reason trade shows remain relevant, even in a digital-first world. They show you the problems manufacturers are trying to solve right now.

We have just come off PACK EXPO Las Vegas 2025 (29 September to 1 October 2025), and it reinforced what we have been seeing across sectors. Companies want cleaner, more automated, data-driven approaches to quality control and to reduce waste without compromising integrity.

Looking ahead, two significant events are on our 2026 calendar: Interpack in Dusseldorf in May and PACK EXPO in Chicago in October. Both matter for different reasons, but the shared value is that they put real customer needs in front of you, quickly.

Quiet operational improvements

Not everything that matters is customer-facing. This year, we have also been improving internal processes across the company, focusing on greater efficiency and scalability.

It is about building maturity. If you want to serve more customers, deliver more complex projects, and support faster development cycles, your internal systems have to keep up. We are also looking ahead to a new headquarters building next year.

The outlook for 2026

If 2025 was about laying groundwork, 2026 will be about bringing more of that work into the open.

Pharma is a significant focus. The platform is ready, the momentum is real, and we are investing in the specialisation required to serve this market properly. At the same time, we are continuing to develop practical solutions for manufacturers who need better options than purely manual testing, but who are not ready to jump straight to full inline inspection.

Ultimately, leak detection should protect product integrity, reduce waste, and align with modern production realities. And this is what we will keep pushing for in 2026.