Material Trends are Changing, and so Must Leak Detection

Sustainability, safety, and speed have been reshaping packaging this year. Brands are moving to recyclable mono-materials, lighter films, paper-forward laminates, and bio-based options, while building smarter packs that protect freshness and support traceability. These shifts are good for the planet and for consumers. However, they also raise the bar for how reliably seals hold, how consistently lines run, and how quickly quality issues are found and fixed.

Materials are evolving faster than many test plans

Reducing the thickness and weight of packaging lowers material use and carbon impact. At the same time, this ‘lightweighting’ can limit how well seals form and make subtle defects more difficult to catch. Mono-material and paper-leaning structures improve recyclability, but they behave differently under pressure and temperature than legacy laminates. In parallel, active and intelligent formats are growing, as are premium finishes that must survive filling, distribution, and retail handling without compromising integrity. All of that puts fresh demands on quality control, and especially on leak detection.

Why destructive tests no longer fit the moment

Bubble tests and sniffer tests were once common because they were simple. Yet both damage the very packs they assess. A bubble test submerges the package in water, while a sniffer test vents tracer gas from inside the pack through a probe, leaving the product unsellable. In an era focused on waste reduction and efficiency, these methods are misaligned with modern priorities. They damage the very packs they assess, create waste, slow high-throughput lines, and rely on operator interpretation. They also offer little in the way of traceable, real-time data. For materials that are getting thinner, lighter, and more recyclable, the industry needs a method that protects product, preserves inventory, and proves integrity with objective measurements. And this must be done without cutting, wetting, or venting the pack.

Non-destructive vacuum decay built for modern materials

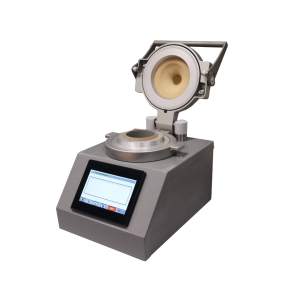

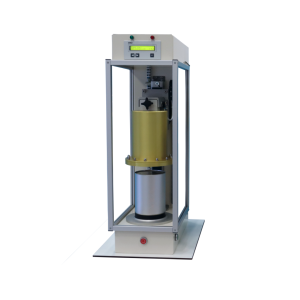

Vacuum decay leak detection answers those needs. By placing a sealed pack in a test chamber and monitoring minute pressure changes, manufacturers can detect leaks without harming the product or the package. The same pack can continue through production if it passes, which supports sampling strategies (or 100% inspection where required) without scrapping saleable goods. This is particularly important as brands transition to new films and recyclable laminates and must demonstrate that changes in structure do not compromise performance.

Automation turns assurance into a continuous process

As lines accelerate and digitalise, quality checks have to keep pace. Automated, in-line vacuum systems deliver pass/fail decisions in real time, tie directly into plant data systems, and provide trend visibility across every shift. That helps teams act early to adjust sealing parameters, isolate a faulty reel, or pause upstream equipment before small drifts become large rework events. The result is less downtime, a reduced burden on labour, and fewer surprises at finished-goods release.

What it means for different sectors

- Food and beverage. Oxygen ingress dulls aroma and accelerates staling. Non-destructive testing safeguards freshness targets and supports shelf-life claims while reducing waste.

- Pharma and healthcare. Integrity is a safety issue as well as a compliance one. Deterministic, non-destructive methods help teams strengthen container closure integrity testing (CCIT) without compromising sterile product or components.

- Pet nutrition and personal care. From pouches to tubs, leak-free packs protect palatability, texture, and consumer trust—especially as brands adopt lighter or recyclable materials.

Smarter packs still need smarter fundamentals

Active and intelligent packaging, think oxygen scavengers, freshness indicators, and NFC and QR for traceability, adds value. However, none of these is a substitute for a sound seal. Non-destructive leak detection underpins these innovations by verifying the barrier that makes them effective. It is the quality foundation for premium aesthetics and new functions alike.

Designing for testability from the start

The most efficient programs bring leak detection into development early. This is done alongside material trials and machinability studies. That way, sealing ranges, sampling plans, and in-line test points are defined before scale-up. It shortens validation cycles and de-risks material changeovers, particularly when moving to mono-material laminates, bioplastics, or paper-centric designs.

The Oxipack approach

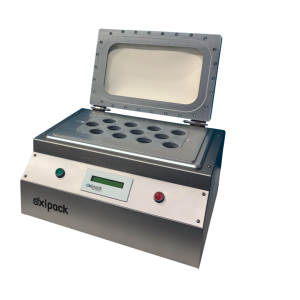

Oxipack focuses on non-destructive, vacuum-based leak detection that fits the realities of production:

- Deterministic, gentle measurement. Packs remain intact and saleable after testing.

- Configurable coverage. From targeted sampling to 100% inspection, systems scale with throughput and risk profile.

- In-line automation. Real-time results integrate with plant control and quality systems to support immediate action.

- Material-agnostic capability. Flexible pouches, rigid containers, and evolving recyclable structures are all supported, including custom tooling where needed.

- Data you can use. Traceable results enable continuous improvement, supplier feedback, and audit readiness.

For operations teams, this turns leak detection from a late-stage check into a continuous, digital proof of performance. For sustainability leaders, it aligns quality with waste reduction by replacing destructive tests and preserving the product. For brand owners, it strengthens the promise on every pack.

Packaging is changing quickly. Lighter, smarter, and more recyclable materials are now central to brand strategy. To make those transitions succeed on the factory floor and in the market, quality control must evolve at the same pace. Non-destructive, automated leak detection is no longer a nice-to-have but a practical, scalable way to protect freshness, safety, and shelf life while reducing waste and cost. That is how packaging materials trends become meaningful outcomes consumers can taste, trust, and choose again.