Thai Plastic Bags Industries

Plastic Film and Plastic Bags

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Thai Plastic Bags Industries (TPBI) is a leading plastic film and plastic bag manufacturer that produces a wide range of plastic products that are sold both in Asia and worldwide. TPBI has quality accreditations for ISO9001/2000, ISO14001/2004, OHSAS18001/2007 and many more.

TPBI’s current product range includes:

- Stretch hood film

- Carrier bags and t-shirt bags

- Fashion bags with different types of handles

- Garbage bags and trash bags

- Food grade LLDPE lamination film

- Compostable bags and sheets for EN13432 standard

- Equilibrium modified atmosphere packaging (EMAP) film for longer shelf life of fresh fruit and vegetables

- Flexible packaging for food, beverages, personal care products, etc.

Stretch hood packaging

Stretch hood packaging protects and secures merchandise on pallets or slip sheets. It uses transparent film so that products can be checked visually. Stretch hood packaging is five-sided, waterproof and strong, and uses less material than other packaging methods. It reduces labour costs and logistics expenses, offers better protection than other packaging methods and eliminates the need for big bags.

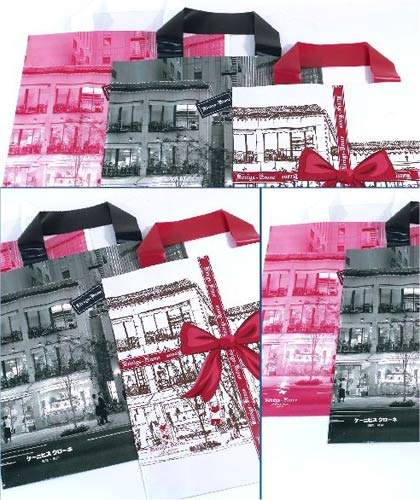

T-shirt bags, carrier bags, fashion bags, garbage bags and trash bags

T-shirt bags, carrier bags, fashion bags, garbage bags and trash bags are a hugely important part of TPBI’s business. TPBI has a fully in-line production operation, over 200 printing machines and over 230 bag making machines.

Food grade LLDPE lamination film

TPBI uses world-class technology in the production of food grade LLDPE lamination film. The facility is located in a clean room to ensure that the lamination film produced is of the highest quality. TPBI’s three-layer co-extrusion extruder produces LLDPE lamination film that has high sealing strength and high clarity, and offers considerable cost savings for customers.

Compostable bags

Biodegradable / compostable bags are the most environmentally friendly bags available. TPBI’s BioPlus compostable bags are EN 13432 certified by DIN CERTCO. They are made from PLA / copolyester blends and are fully biodegradable; they eventually become a nutrient source for microorganisms in the microbial food chain.

Equilibrium modified atmosphere packaging (EMAP) film

Equilibrium modified atmosphere packaging (EMAP) can extend the shelf life of produce such as fresh fruit and vegetables by slowing down the respiration rate of the produce. EMAP can extend the shelf life of produce by up to five times compared with normal plastic packaging (depending on the type of produce, storage temperatures, etc.).

Flexible packaging

TPBI’s flexible packaging unit operates with gravure printing and dry lamination on most types of film, including BOPP, PET, ONY, KNY and LLDPE. Flexible packaging is used to protect, display and dispense products. The main applications for flexible packaging are:

- Hygiene products

- Softener

- Detergent

- Frozen foods

- Liquid foods

- Snacks

- Pet foods

Contact Details

Website

Email Address

Address

Nakornpathom,

Sampran,

73210,

Other,

Thailand