Coding: a long running tradition

Coding was the primary concept on which early anti-counterfeiting systems were based. Today, coding maintains that role and underlies the sophisticated packaging innovations available to pharmaceutical industries in the 21st century. Since first appearing on consumer goods in 1974 when added to chewing gum, manufacturers and suppliers have since universally adopted the barcoding of goods.

The barcode is a series of numbers which, when decoded, identifies the product by date and place of manufacture, type of product, batch or serial number, or any other factor the user encodes into it. While ground-breaking when introduced, these codes are one-dimensional (1D) and as a result the information that can be included in them is limited by the maximum available number of characters that can be scanned or printed at one time – generally ten to 20. Furthermore, these codes necessitate reference to a database guide in order to accurately decode the information.

Modern coding: going 2D

The development of the two-dimensional (2D) barcode has been exponential. The 2D code can now accommodate thousands of characters, and scanning techniques allow the code to be used for multiple purposes. The more sophisticated technology employed in these systems facilitates the transfer of the scanned information to other devices, such as smartphones and websites, enabling almost instant verification of goods and packaging.

This technology is therefore a valuable tool in the detection of counterfeit products. Indeed, these codes mean that the location of a consignment at any stage of the logistics chain can be determined, including items as small as pills, bottles, compounds and products basic to the pharmaceutical industry.

GS1 Healthcare, the industry standards group based in Brussels, Belgium, has approved a number of drug packaging data standards, including GS1 DataMatrix, which has been designed for tiny 2D barcodes that can fit on unit-of-use drug packages as small as ampules.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThese 2D barcodes have proved so effective when compared to 1D barcodes that the Food and Drug Administration (FDA) is reconsidering its rule that a linear barcode with the National Drug Code on is required on most unit-of-use packages. This reconsideration is welcomed within the pharmaceutical sector, with Kendra Martello of the Pharmaceutical Research Manufacturers of America (PhRMA) believing that: "After 2016, only 2D barcodes should be used, consistent with manufacturers’ migration to the use of 2D barcodes for other applications."

Beyond 2D: using radio frequencies to combat counterfeits

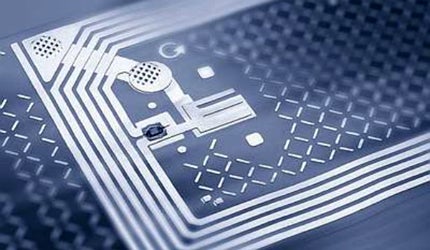

Radio frequency identification devices (RFID) are tags that use radio frequency electromagnetic fields to transfer data from a product to a reader, with the RFID being unique to a given product. The advantages of the RFID over 2D barcodes are that the product and the RFID reader can be located at greater distances, and do not have to be in a straight line, or even visible to each other.

In addition, the tag can be embedded into the product, eliminating the opportunity for it to be tampered with or removed and attached to another product. This has obvious value as an anti-counterfeit measure and is one of many reasons why the FDA has stated that RFID’s are "the most promising technology for implementing electronic track and trace in the drug supply chain."

Richard Burhouse, business development manager of Payne Security, a global leader in protecting some of the world’s largest brands, told us that: "There is definitely a place for RFID, especially for pallet tracking, etc. The lack of requirement for contact and / or line of sight is the critical benefit here, especially as part of a complete track and trace programme."

However, he also warns that: "Infrastructure and item costs are prohibitive for low cost items and the versatility and the low cost of 2D barcodes means that these have eclipsed their likely use." Indeed, despite the advanced utility of RFID, it is unlikely to supersede the barcode for all purposes as it is more expensive, and cannot be printed, copied, or transferred electronically. Therefore, instead of being competing anti-counterfeiting innovations, the two technologies complement one another, as neither can have universal application. For instance, barcodes can be applied to give a unique identifying configuration to a pill, while RFID’s can track the packaged pills from the source to the retailer.

The advanced barcode: data glyphs

Data glyphs are a more advanced barcode technology in which tiny digital encrypted marks (or glyphs) are used to encode information, increasing scope for the inclusion of detailed packaging information. There is wide potential for their use for invisibly coding the packaging of pharmaceutical products, especially in conjunction with advances in digital imaging software.

A report by Transcrime, a joint research centre on transnational crime set up by Università Cattolica del Sacro Cuore of Milan and the University of Trento, cites Cryptoglyph Digital Security Solutions as an example of technological best practice. This is a digital security solution created by AlpVision, a Swiss company specialised in invisible digital technologies.

The prime purpose of these technologies is product authentication, and the true innovation lies in the fact they can be used as both an on-packaging and on-product anti-counterfeit measure.

Future for anti-counterfeiting innovations

The advantages of barcoding to business operators in the retail sector are well known, but their utility as an anti-counterfeiting measure in the war against fake pharmaceuticals is becoming more established. The protection offered by barcodes and other innovative packaging strategies can ensure that at each stage of the supply chain, pharmaceutical goods can be monitored and the integrity of the process guaranteed.

However, it is important to not rely purely on these packaging innovations. As Richard Burhouse reminds us: "It’s critical to understand the problem the brand owner is trying to overcome – just putting technology onto packaging and expecting it to stop counterfeiting is no good to anyone without a well thought out programme on how to identify and enforce."

Related content

Weird science: using DNA authentication to fight counterfeit packaging

Counterfeiting in the packaging industry is a major problem that needs to be tackled efficiently and cost effectively.

Packaging lightweights – ultra-light and thin packaging innovations

Amid constant financial pressure and consumer demands for greener and more sustainable packages, the packaging industry is in a constant battle to save on costs and production materials.

Printed electronics: high tech on a small scale

Could printing with electronic displays or RFID usher in the next generation of packaging?

Tackling pharmaceutical counterfeits: beyond packaging

With a large proportion of the developing world unable to afford genuine medication, black market counterfeits are the only option for many.