Harpak-ULMA has revealed a high-speed grind-line application for its Mondini Trave Sinfonia tray-sealing platform, designed to boost the output of ground-meat packaging.

The system is designed to replace conventional tray-sealing processes with a higher-capacity approach.

The Sinfonia technology uses software-driven magnetic transport, moving trays on individual shuttles with precise control.

Harpak-ULMA reports that this configuration raises production rates from around 120 packs per minute to up to 200 packs per minute, approximately twice the speed of typical mechanical tray sealers used in grind-line operations.

The company highlighted that standard mechanical systems rely on components such as belts and pusher arms, which can slow down sealing speeds and are particularly limiting for low-oxygen modified atmosphere packaging.

The Sinfonia design eliminates these elements, allowing for increased throughput.

Launched in 2023, this deployment marks the first time the Sinfonia system has been adapted for grind-line settings, where maintaining tray integrity and managing contamination risks have previously limited processing speeds.

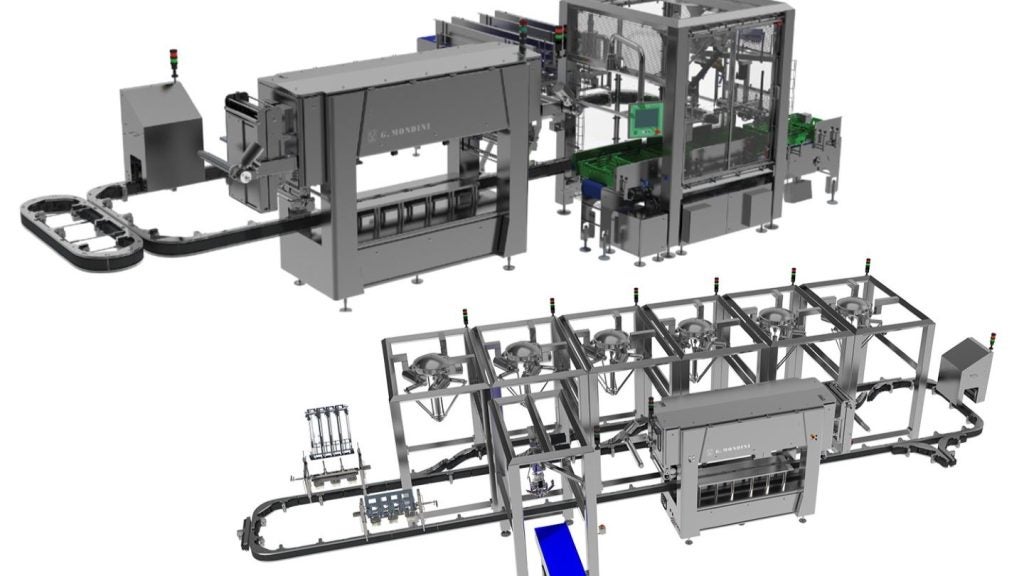

The adapted solution brings together portioning, dual denesting, retractable conveyor loading, and a 14-up sealing array.

Each station operates independently, without being restricted by fixed conveyor mechanics.

The new setup is intended to offer a more consistent tray path, reduce contamination risks, and simplify product changeovers while keeping the overall footprint compact.

Harpak-ULMA tray sealing product manager Carlo Bergonzi said: "The competitive ceiling for grind-line tray sealing is around 120ppm. With Sinfonia, we can engineer a 200ppm grind line—almost a 100% throughput increase. Sinfonia fundamentally changes what's possible in ground-meat tray-sealed packaging.

"By controlling each tray independently, we remove the mechanical constraints that typically dictate line speed. The result is a faster, cleaner, and far more stable tray-sealing process that simply isn't achievable with conventional systems. Given the momentum behind meat-brick formats across major retailers, this application directly addresses the performance conversations we’re hearing from processors as they head into IPPE 2026.”

Last year, Harpak-ULMA introduced the ARTIC SS Chevron flow wrap machine for medical and pharmaceutical packaging applications.