Specifically developed for use in Delta robots, the NDF enables extremely fast changes of direction thanks to a low-inertia clamping system at the input stage, as well as a remarkably torsionally rigid structure. At the same time, the torsional backlash is limited to < 1 arcmin as a standard feature.

The output of the NDF has also received special attention in order to optimally meet the specific requirements of a Delta robot: The gear ratio at the output is i=5.5, which allows transmission of very high torques. A special radial shaft sealing ring ensures optimum sealing of the shaft during rapid changes of direction. A food-grade oil lubrication system, a stainless-steel output shaft and a nickel-plated output flange are available as options for the NDF.

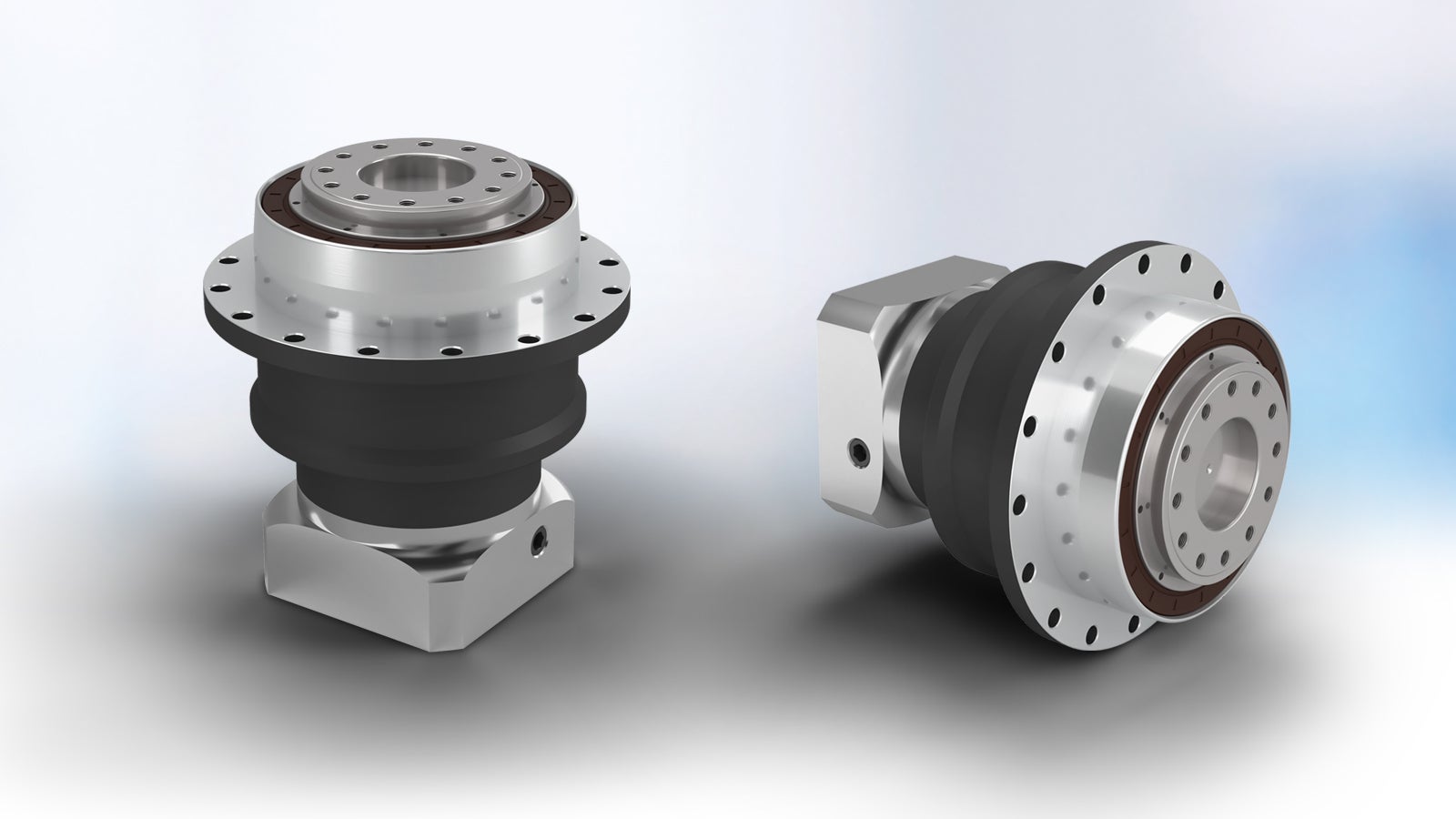

Features

- Application-specific gearbox

- Coaxial gearbox

- Helical gear

- Preloaded angular contact roller bearings

- Rotary shaft seal

- Torque interface

- Equidirectional rotation

- Planet carrier in cage design

- Four planet gears at the output

Testimonial

“The reliability of the gearboxes is an absolute must for us in order to meet our customers’ expectations to their complete satisfaction. In our view, the NDF gearbox from Neugart offers the best overall package of performance, quality and cost efficiency. During the development of our new RPP machine platform, we worked very closely and intensely with the Neugart company and thus found the ideal gearbox solution for us.”

Andreas Schildknecht and Marco Ebner | Syntegon Packaging Systems AG

Options

- Nickel plating and stainless steel to protect against corrosion

- Food grade lubrication – lubricant is certified to NSF H1 and ISO 21469

- Wide range of output shaft options – equipped with an interface to ISO 9409-1 or can be made of steel or stainless steel and with or without a dowel hole

Read more: https://www.neugart.com/en/gearboxes/application-specific-gearboxes/ndf