Piramal Glass, a provider of glass packaging solutions, is expanding its existing packaging plant in Jambusar in the Indian state of Gujarat. The estimated investment in the expansion project is Rs3bn ($42m).

The packaging facility has a workforce of 2,130 and the expansion is expected to employ 700 more personnel. The expansion will allow Piramal Glass to service its customers with innovative glass packaging solutions.

Piramal Glass Jambusar packaging plant expansion details

The plant will be spread across an area of 300,000ft² and the expansion will add a new 250 tonnes per day (TPD) furnace, along with seven new production lines. It will be able to supply products to the food and beverage, high-end speciality spirit, and pharmaceutical markets, with a focus on exports to customers in Europe, Asia and the US.

The expanded facility will meet the increasing demand for food packaging, water bottles and spirits bottles.

Piramal Glass existing facility details

The existing plant in Jambusar has one of the largest single installed capacities in the world, manufacturing amber-glass products for pharmaceutical packaging. It is involved in the production of Type III amber-glass bottles and vials for pharmaceutical firms and Type III flint bottles for industries such as speciality food and beverage, pharmaceutical, and cosmetics and perfumery.

The existing infrastructure at the facility includes three furnaces with 23 manufacturing lines. The packaging plant has a glass production capacity of 540TPD and features advanced technology with an emphasis on digital manufacturing.

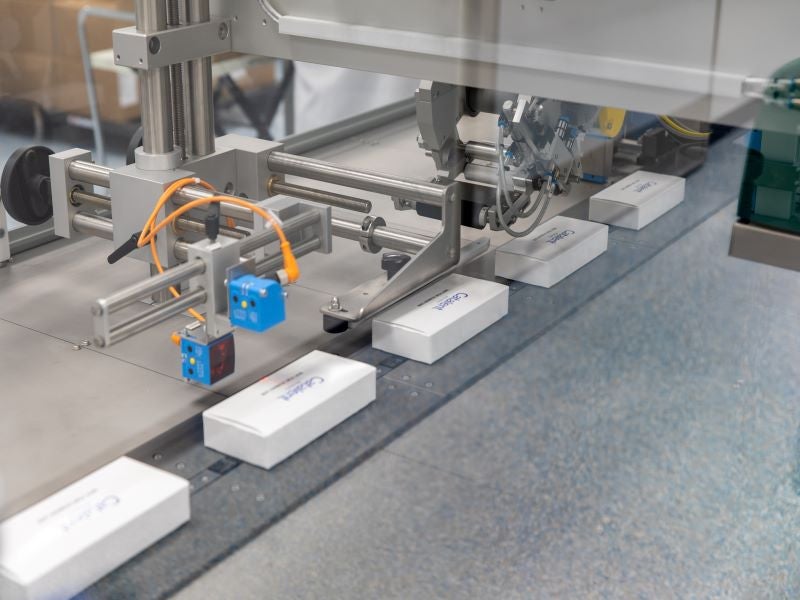

In November 2018, the company installed Microsoft’s Azure IoT platform Real-Time Manufacturing Insights (RTMI) on 46 production lines across its four facilities, including Jambusar. The IoT solution provides real-time visibility into line manufacturing operations, allowing Piramal Glass to identify and evaluate production line losses at different stages using data from sensors on the production lines.

Sustainability features implemented by the company

The furnaces utilised by the company are designed to provide greater efficiency and reduced emissions. Some of the furnaces have electric boosting capability for increased energy efficiency while all of the furnaces are compatible with dual fuel systems.

The company’s sustainable initiatives include the implementation of glass recycling, which helps in conserving energy. The company holds ISO 14001 Certification and supports glass recycling of post-consumer recycled (PCR) glass to reduce waste generation, emissions, and environmental impact. It aims to incorporate 60% of the used glass in glass production.

Piramal Glass installed roof-top solar power systems at its facilities in India with a generation capacity of 2MW. Its plant in Sri Lanka has a 3MW solar roof-top system. The company is looking to expand the use of solar power and the development of large-scale solar farms.

The company also intends to increase the quality and quantity of the recycled glass and reduce the waste production.

Piramal Glass packaging product portfolio

The product offerings of Piramal Glass for the pharmaceutical sector include Amber Pharma bottles for syrups, tablets and chemicals, and infusion and injectibles for the vials category. The company also produces borosilicate type-1 glass containers.

The products and packaging solutions offered by the company for the perfumery segment include glass bottles for foundation, nail polish, perfumes and skincare. Piramal Glass’ customer base comprises 17 of the world’s top 20 brands, including LVMH, Coty, Yves Rocher, and Sisley. The company provides decoration services in different types of glass bottles for the cosmetics and perfumery sector.

The offerings in the food and beverage sector include glass bottles for ketchup and dressings, spice jars, water, jam jars, coffee, liquor and beer.

The company enhances its product portfolio by focusing on the continuous design and technical support for the development of innovative products.

Marketing commentary on Piramal Glass

Piramal Glass is one of the world’s fastest-growing glass packaging firms and has expertise in production, design and decoration of niche glass packaging solutions.

The company provides end-to-end glass packaging solutions to customers across 60 countries, serving multiple industries such as cosmetics and perfumery, pharmaceutical, and speciality food and beverage.

It bought Sri Lankan firm Ceylon Glass Company in 1999 and became the largest supplier in the pharma sector.

Piramal Glass has design, production, and decoration facilities in India, Sri Lanka, and the US with a total of 12 furnaces and 55 production lines. It operates through offices and warehouses in different locations, including Spain, France, UAE, Germany, India, the UK, China, Turkey and Sri Lanka.