Amcor Fibre Packaging has invested $22 million in its Scoresby, Victoria, Australia, plant to increase the production of preprint liners for corrugated boxes. The company officially opened its new facility in May 2003. The plant has installed one of the largest automated preprinters commercially available from Fischer & Krecke of Germany.

The Fischer & Krecke 94 DF-CNC flexographic press took three years to design and required the extension of the building it was to be housed in by 5m. The building also required a new post-tensioning floor to accommodate the 40t weight of the new press.

The extension of the plant is Amcor’s response to the over-demand on its existing Fischer & Krecke equipment at the Scoresby plant. During the last decade, there has been an increase in the demand for point-of-sale graphics from the wine and fresh produce markets.

94 DF-CNC fexographic press

The 94 DF-CNC flexographic press can print up to eight colours, plus a layer of varnish at a rate of 300 linear m/min. The system has a state-of-the-art print fault detection system that includes an in-line editing facility, which can reduce downtime and paper wastage.

The machine has a robotic cylinder storage and loading system, which saves time and significantly reduces any operator involvement, thus increasing the level of safety. With the programmable cylinder handling system, plate cylinders and anilox rolls can be changed quickly and safely.

Cylinder changes are programmed via the operator control system (OCS). The cylinder design is identical to the previous press, allowing them to be swapped between presses; thus, the initial company investment in cylinders is not lost (approximately $10,000 each). The press allows the printing of 2.5m web with a 2.45m cylinder repeat.

System automation and control

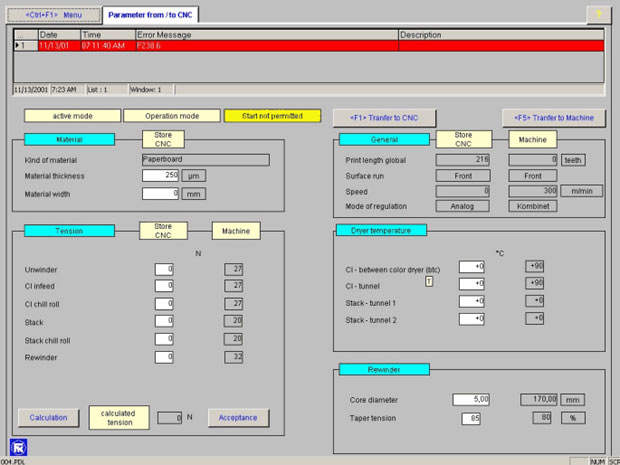

The 94 DF-CNC system has a 32-bit microprocessor control system, which uses real-time data processing for instant machine response that eliminates the need to wait for the press to warm up. The press has a modem link to Fischer & Krecke in Germany, allowing the company to access production process information and address any problems online. The user interface of the computerised numerical control (CNC) is clearly structured so that inputs can be made easily and safely and incorrect inputs are rejected.

The print units can be adjusted with a resolution of 1µ (0.001mm) and the registers with a resolution of 10µ (0.01mm). The CNC is linked with the OCS, the centralised monitoring and control system of the machine. This ensures fast transfer of data between the two systems, and user-friendly saving or reloading of a print job.

This new facility averages one roll of printed material an hour, with a one-hour changeover between new jobs. Previously, it used to take around four to five hours per changeover.

Amcor preprint in Australia

Amcor has been running a preprint division in Australia for around 14 years. Originally based at Clayton, the preprint facility was relocated to Scoresby in 1994. Amcor’s preprint business is part of the Amcor Fibre Packaging Australasian (AFPA) division. AFPA produces over half a million tonnes of corrugated box material annually, primarily for the fresh and processed food and beverage industries.

Environmental impact

In 2008, Amcor signed an agreement with Knox City Council to supply water collected from the roof of the plant to irrigate 1,500 street trees. Amcor will collect about one million litres of water each year and has installed a 150,000l BlueScope Water tank at the facility.