Tethered Caps: High-Speed Assembly with Contexo's All-in-One Machine

For over 30 years, Contexo has been designing systems for complex closures and innovative complete systems manufactured in plastic.

Contexo provides caps and closure high-quality machines for the beverage and packaging industries.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Contexo offers high-quality packaging solutions that scale flexibly with the customer’s needs. Many well-known sports caps and carton closures are produced by the company’s assembly machines, which are characterised by their technical perfection, high efficiency, and versatility.

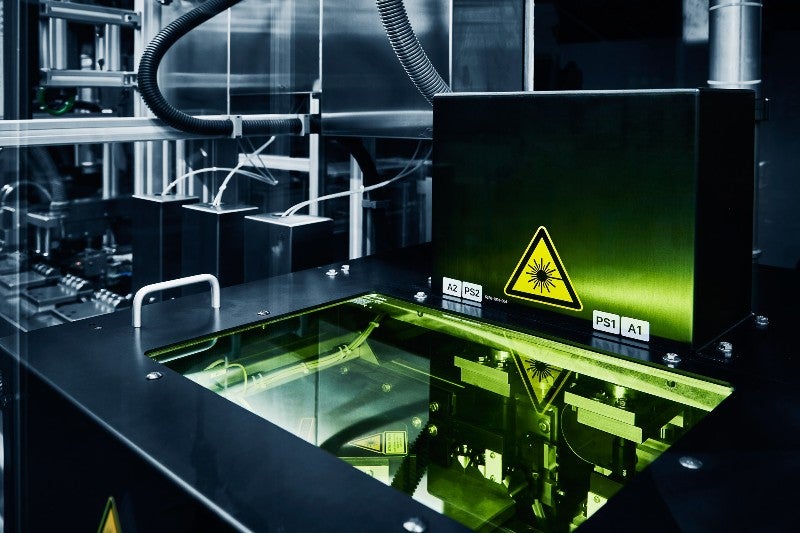

Contexo brings innovation to the packaging industry with its all-in-one solutions. One major advantage that the company brings to its clients is the ability of up to 65 production stages to be integrated into one system. These include assembly, imprinting, joining, glueing, welding and lasering.

In addition, Contexo provides full service from a single source, thereby simplifying procedures for the customers through time and cost-saving solutions. Whether tethered caps, carton closures, PET closures or pouches, the company offers assembly machines for all types of caps and closures.

Contexo is continually developing its technologies and is thus attracting more and more closure manufacturers.

The company helps customers boost their profit through a range of services:

Contexo provides machine solutions for every type of closure, ranging from tethered caps, sports caps, push-pull, hot-fill, TE caps and single-part caps. With vast experience and the know-how to adapt its services to every client’s closure needs, Contexo is one of the most in-demand companies in this sector.

Every 1/600th of a second, a new beverage closure is assembled, folded, slit, inspected several times and packed by Contexo’s beverage-closure machines.

One of Contexo’s basic characteristics is innovation in design and production, and therefore the company handles assembly requests that are rejected by other machine builders as it completes tasks quickly, simply and at low cost.

Assembly speed is only one condition required for high market-conform output rates. The market now expects zero defects, and end products must be 100% error-free.

Therefore, many producers have launched additional inspection machines in recent years so that they can meet the high-quality criteria and the demands of the packaging industry.

However, Contexo’s machines can only inspect the assembled parts after the production process. This results in a larger installation area and slower completion times, which, in turn, means higher costs and slower overall production rates.

In addition, a finished beverage closure cannot be illuminated with full reliability. Contexo offers a solution to these challenges by introducing a different quality control approach.

Contexo has adopted a different method for quality control: not only is the finished closure inspected after assembly, but each component is also inspected beforehand.

For this to work, the inspection systems are integrated inline into the assembly machine and work in sync with it. The additional system enables the full inspection and evaluation of all the closure´s features.

The market for closures is facing major challenges, and the EU directive on reducing plastic waste, known as the ‘Single- Use-Plastics Directive’, stipulates that from July 2024 caps must be connected to the bottle (‘tethered caps’) so that plastic waste is reduced.

Currently, there are challenging tasks for the manufacturers of caps and closures as new closures need to be manufactured or existing ones need to be revised to meet the new requirements.

Contexo offers a manufacturing solution that sets new standards through a machine platform that integrates all the necessary processes in just one system. It is specifically developed and designed to present an all-in-one technology that handles everything from assembly to folding and roll slitting of the TE band to closing and packaging.

For over 30 years, Contexo has been designing systems for complex closures and innovative complete systems manufactured in plastic.

Contexo is taking part in Drinktec, the international trade fair for the beverage and liquid food industry, in September 2022.