The Internet of Things is taking hold, helping packaging providers make the move from being merely reactive to being predictive. Subsequently, as Ryan Ellington finds, opportunities abound for companies to gain a substantial advantage over their industry peers

Recent research from Packaging Gateway’s parent company, GlobalData, has shown how companies are starting to use the Internet of Things (IoT) to enhance the efficiency of their operations. Within packaging, the leaders, according to GlobalData’s ‘Internet of Things in Packaging – Thematic Research’, include Tetra Pak, Amcor & Berry Global, all of whom are implementing IoT to help deliver their ESG targets.

IoT – The way forward

As in all other industries, the breadth of data that packaging companies possess can provide significant opportunities to locate efficiency opportunities. Integrated smart systems, processes, sensors, data and analytics are helping packaging manufacturers make smart decisions, automate processes and reach efficiency and cost-saving targets – all of these come under the remit of IoT.

Industry observers believe IoT initiatives can often be the starting point of digitalisation. Peripheral technologies, such as 5G and artificial intelligence (AI), provide support and enhancements: IoT collects the data, 5G transmits it, and AI extracts the insights.

“Companies in all sectors are increasingly looking to digitalise their supply chains and make faster and better-informed decisions based on the data collected,” says GlobalData analyst Luke Gowland. “Fully integrating interconnected technologies like IoT, AI, cloud and edge computing through the entire packaging value chain represents a significant opportunity.”

Gowland notes: “IoT as a service (IoTaaS) vendors provide various platforms to assist organisations with IoT deployment without in-house expertise. IoTaaS aims to make it easy for enterprises to deploy and manage their connected devices, and has become an accelerator for IoT adoption, especially in predictive maintenance, advanced automation and condition monitoring.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData“As the world recovers from COVID and economic growth returns, IoTaaS revenues will grow dramatically. Accenture, IBM and Microsoft are among the providers likely to see the biggest demand for their services.”

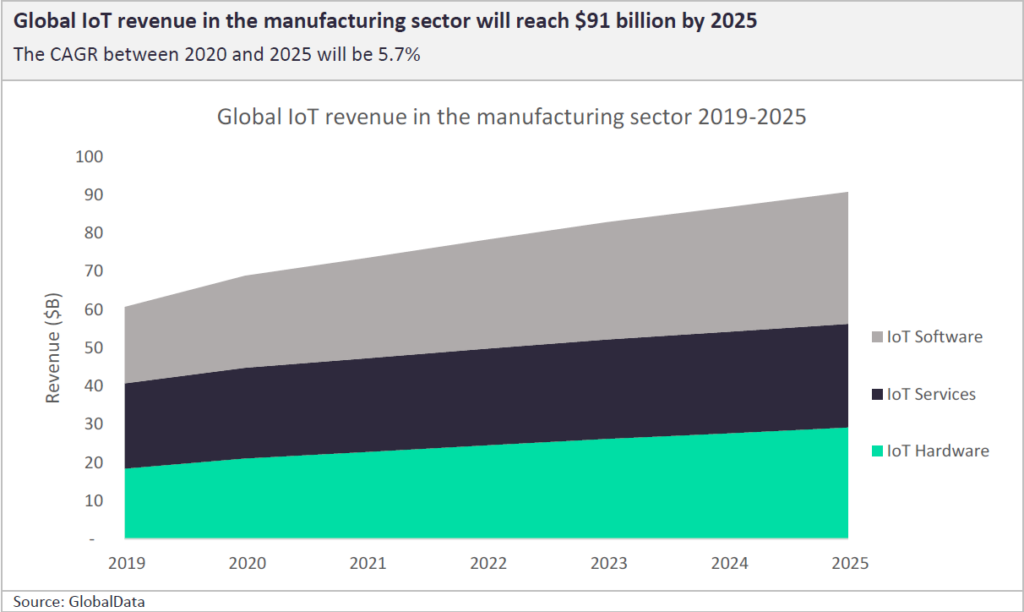

Indeed, the increased use of IoT has resulted in its growth across all industries, not just within packaging. GlobalData estimates that in manufacturing, global IoT revenue will reach US$91bn by 2025, up from $69bn in 2020. This represents a compound annual growth rate of CAGR of 5.7%.

IoT and the environment – A perfect match

Among the most critical challenges for packaging companies is environmental sustainability. As a tool to fight this challenge, IoT could be the silver bullet. According to the World Economic Forum, for example, combining IoT with 5G and AI could help cut carbon emissions by 15%.

The use of IoT is becoming an integral aid in reaching ESG targets. By implementing IoT into their operations, businesses are able to get closer to – or achieve – their goals in areas like energy reduction in manufacturing by streamlining their operations and running more efficient enterprises.

US-based packaging giant Ball Corp, for example, has partnered with AI software provider C3 AI to collect data from 60 of its facilities around the world. The software is used to track, aggregate, manage and report energy use at the sites. This contributes to Ball’s global sustainability goals of transitioning to 100% renewable electricity by 2030 and achieving net-zero carbon emissions before 2050.

Another example is Tetra Pak’s commitment to investing around EUR100m (US$113.8m) per year over the next five to ten years to develop more sustainable packaging solutions. As part of this transformation, Tetra Pak has invested in Microsoft Azure IoT solutions such as Azure IoT Hub to create ‘smart factories’ that drive sustainability across its whole organisation. The group uses Azure IoT Edge devices to advance the operational efficiencies at its customers’ facilities around the world, targeting predictive maintenance and monitoring overall equipment effectiveness.

“Tetra Pak is going through a major transformation in sustainable manufacturing,” says Tetra Pak Digitalisation & Automation Director Peter Stolt. “With our investment in Azure IoT Hub, Tetra Pak now has the technology to help optimise our processes and innovate for a more sustainable future.

“Being able to connect anything we want to Azure’s infrastructure opens new possibilities for us to control our processes better and, ultimately, improve quality and reliability for our customers.”

Luxembourg-headquartered glass producer Ardagh has implemented ‘Water Flow Intelligence’ at two of its US facilities. Built on Ecolab’s ‘Ecolab3D’ platform, IoT-enabled devices collect and transmit real-time data on water usage at enterprise, plant and asset levels, which can be stored in the cloud and viewed using a dashboard.

The use of IoT to fight the good fight for environmental sustainability doesn’t concentrate solely on factories. Paper & pulp manufacturer Stora Enso has started to apply IoT within their forests through the digitalisation of operations.

The Finnish company is looking to use the technology to make gains on its ambition to offer 100% regenerative products and solutions by 2050. Moves include the use of drones for forest inventory, virtual visits of forests and improved decision-making through the use of AI and satellite imagery.

The current packaging leaders

The research from GlobalData also features the company’s proprietary thematic scorecard, which rates packaging companies against their rivals across a variety of themes. Among the companies leading the way in IoT activity are Berry Global, Tetra Laval International, Tetra Pak’s parent company, and Amcor.

Berry, which specialises in manufacturing plastic packaging, has targeted a reduction in annual energy consumption of 3% across all its sites. To achieve this, the group has partnered with ‘industrial internet’ specialist Newsteo. At its Bailleul facility in France, Berry has installed an IoT system to remotely read electricity, gas and water meters, allowing the company to monitor its energy consumption in real-time. The system detects and remedies abnormal water consumption, resulting in a daily saving of around 10m³ of water.

Earlier this year, UK packaging specialist Amcor invested in PragmatIC Semiconductor. The US$5m spend will help the electronics company continue to develop technology used in delivering smart applications throughout the packaging lifecycle, such as PragmatIC’s ‘ConnectIC’ line of radio frequency identification and near-field communications (RFID/NFC) integrated chips. This type of tech is able to store and transmit data in order to, among other things, monitor freshness.

Meanwhile, Finland-based Stora Enso – which does not appear yet in GlobalData’s ‘Top Ten’ – is utilising IoT to collect data from its production lines to help streamline operations. In late-2018, the paper packaging specialist installed sensors on the hand valves in its factories. The sensors send data to each facility’s mill control system to give the production personnel an overview of the mill’s piping system.

IoT is making its presence felt in all industries, packaging included. Companies that fail to prioritise – and invest in – IoT will struggle to survive in the years ahead.