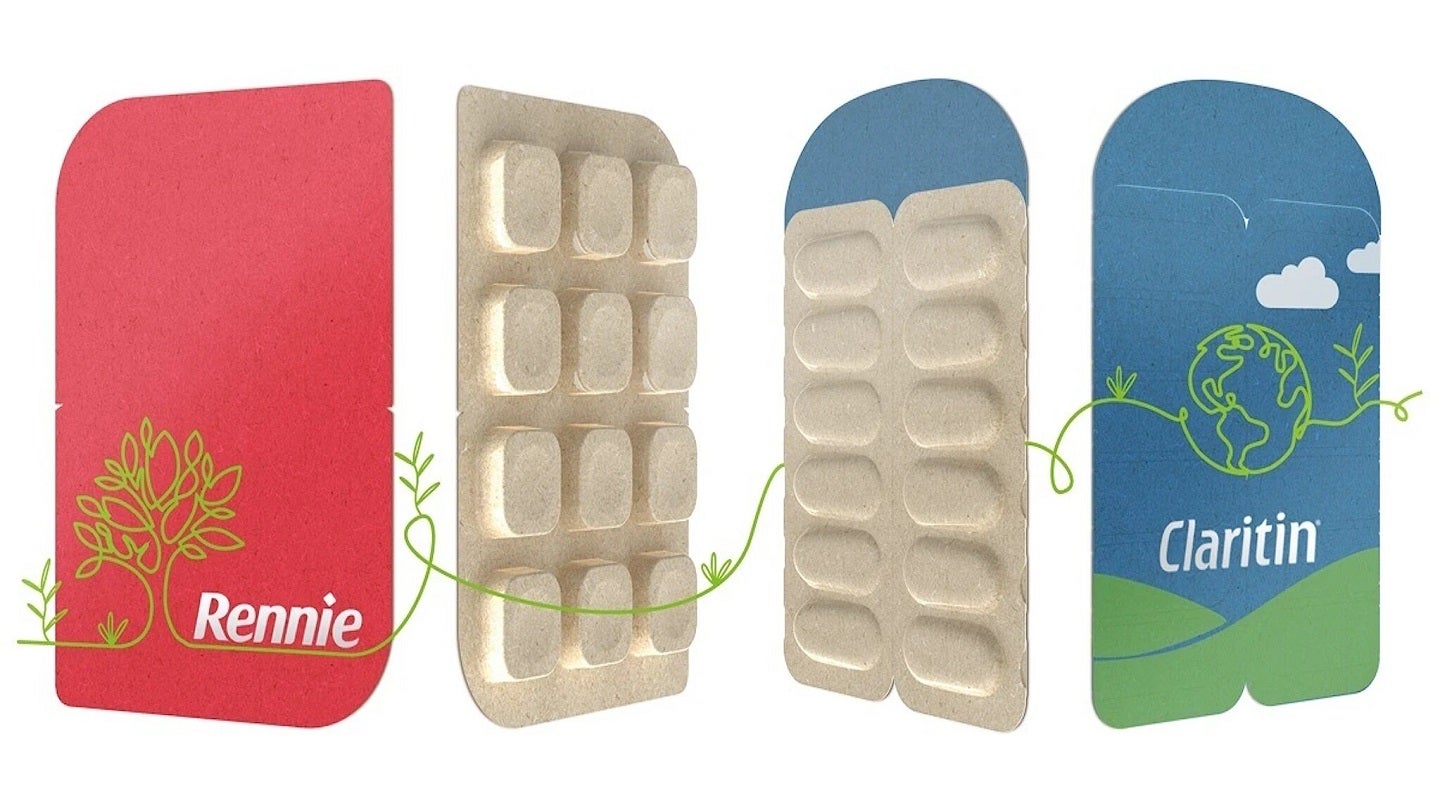

Bayer’s Consumer Health division has joined the Blister Pack Collective, which was formed by PA Consulting and Swedish research and development company PulPac.

The Blister Pack Collective uses Dry Molded Fiber technology to convert renewable plant fibres into sustainable packaging and products.

Compared with single-use plastics, the fibre solution is said to be a scalable and affordable alternative that offers a superior environmental footprint.

Bayer Consumer Health Global Packaging Innovation director Jesse DelGigante said: “We have a bold commitment to transform 100% of our packaging to be recyclable or renewable by 2030 and have committed to invest €100 million investment in changing how our products are made and consumed.

“Achieving this will require working with the best partners and we are proud to be a part of the Blister Pack Collective as we work to make a real impact for sustainability.”

The collective is inviting pharmaceutical, consumer health, and fast-moving consumer goods businesses to join it to expedite the development of the Dry Molded Fiber blister pack and transition from polyvinyl chloride (PVC) packs.

In relation to sustainability, the solution is said to be able to eliminate more than 100,000 tonnes of plastic medicine packaging annually and reduce carbon dioxide emissions by up to 80% when compared with plastic alternatives, as well as minimise water usage.

In July this year, PulPac signed a new agreement with Matrix Pack to license its Dry Molded Fiber technology to Matrix for use in manufacturing its sustainable product range.